Blog

What Is Color Thermal Transfer Ribbon and Why It Matters in Industrial Labeling

Introduction

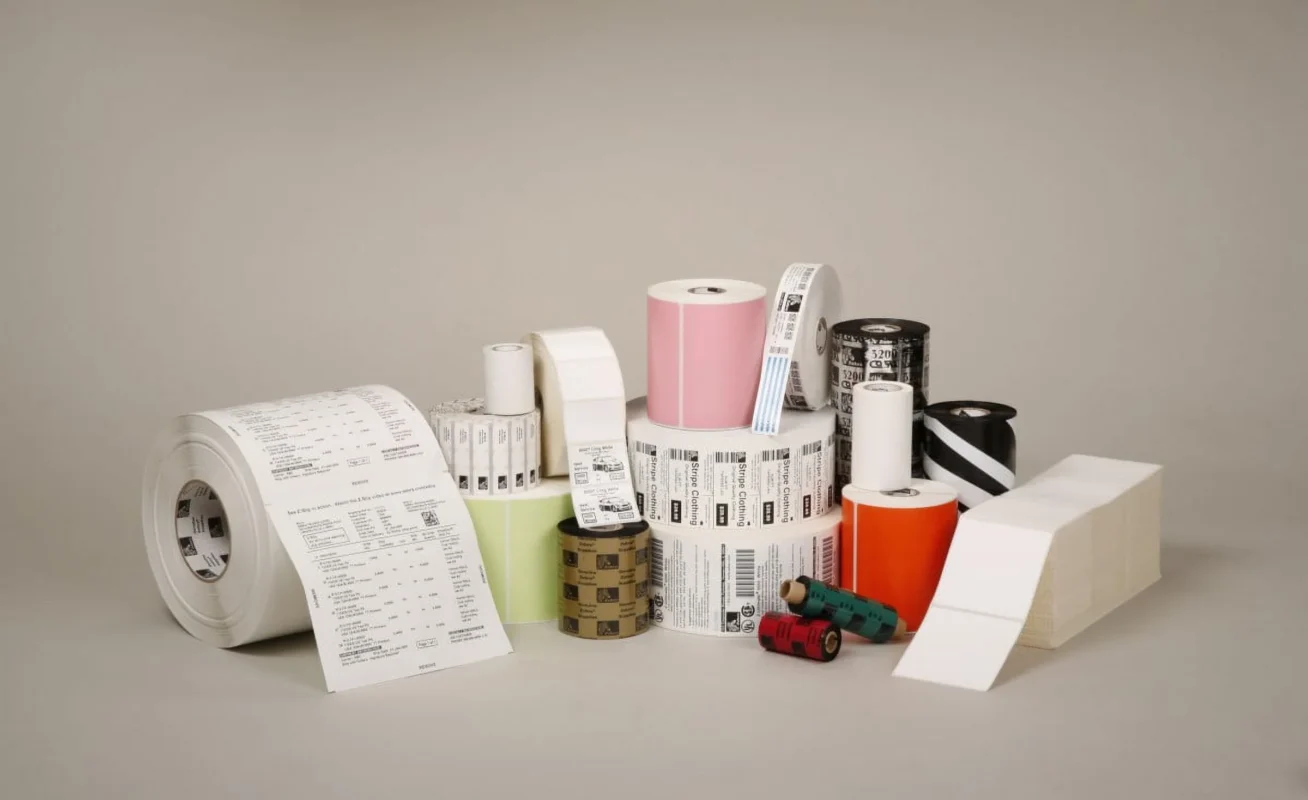

Industries that emphasize labeling for safety and related purposes experience a rapid increase in the need for superior printing supplies. The color thermal transfer ribbon emerges as a vital asset for manufacturers and distributors because it enables them to create eye-catching and durable labels that fulfill both operational needs and branding requirements.

This guide explains to distributors, procurement officers, and industrial operations managers about color thermal ribbons including their definition, differences from standard ribbons, applications, selection criteria and bulk ordering tips.

What Is a Color Thermal Transfer Ribbon?

The color thermal transfer ribbon functions as a coated film within thermal transfer printing systems to print colored ink onto labels by using heat. Color thermal transfer ribbons feature a wide spectrum of colors including red, blue, green, yellow, white, and silver to enhance visibility and provide unique branding and categorization options.

The construction of these ribbons involves multiple layers which usually consist of:

- A PET base film

- A release layer

- The ink layer contains a blend of color wax and resin or wax-resin materials.

Heat from the printhead melts the ink layer which transfers onto the label resulting in high-quality colored prints.

Why Use Colored Thermal Transfer Ribbons?

1. Improved Visual Communication

The use of color printing enables operators along with customers and inspectors to rapidly understand critical data.

- Warning symbols

- Date codes

- Product categories

- Regulatory markings

2. Enhanced Branding

Companies can print custom-colored texts and symbols that match their brand guidelines without needing pre-printed labels by using colored ribbons.

3. Better Material Differentiation

Color-coded labels facilitate better workflow in warehouses and production lines through visual separation of different elements.

- Inventory zones

- Order types

- Handling instructions

4. Compliance & Safety

Color-coded symbols serve as safety requirements in multiple sectors including chemicals, pharma, and electronics.

- GHS/CLP icons

- Hazard warnings

- Medical identification

Types of Color Thermal Transfer Ribbons

1. Wax Color Ribbons

- Best for paper labels

- Moderate durability

- Low cost

- Shipping labels and basic inventory management benefit from its use in shelf tagging.

2. Wax-Resin Color Ribbons

- Suitable for coated paper and synthetics

- Good scratch and smear resistance

- Better longevity and chemical resistance

3. Resin Color Ribbons

- Resin Color Ribbons work well with synthetic materials such as PET, PVC, PP.

- High durability, ideal for harsh conditions

- Excellent resistance to abrasion, solvents, and heat

- Common in electronics, automotive, pharma

Available Colors and Their Industrial Uses

| Color | Typical Use Case |

|---|---|

| Red | Warning labels, promotions, reject tags |

| Blue | Inventory codes, cold chain, healthcare |

| Green | Eco-products, safety zones, approvals |

| Yellow | Attention-grabbing labels, storage flags |

| White | Dark material labeling, overlay printing |

| Silver | Branding, electronics, asset tags |

| Gold | Premium packaging, awards, certifications |

Key Applications by Industry

1. Logistics and Warehousing

- Color-coded zone identification

- Inventory category tagging

- Return and damage indicators

2. Food and Beverage

- Product classification

- Promotional stickers

- Expiration date visibility

3. Healthcare and Pharmaceutical

- Sample labels and dosage identifiers

- Regulatory symbols and barcodes

- Medical supply sorting

4. Manufacturing

- WIP (Work in Process) labeling

- Assembly part sorting

- Safety instructions

5. Electronics and Automotive

- Serial numbers and batch codes on components

- High-temp labeling with resin ribbons

- Brand color-matching asset tags

Selecting the Appropriate Ribbon Color to Suit Your Purpose

Step 1: Know Your Label Material

- Uncoated paper: Use wax

- Coated paper or PP: Use wax-resin

- PET, PVC, or film: Use resin

Step 2: Determine Durability Requirements

- Does the label face exposure to friction forces or experience heat or chemical contact?

- Choose ribbon type based on resistance needed

Step 3: Confirm Printhead Compatibility

- Most industrial printers use flat-head ribbons

- Verify ribbon dimensions (width, length, core size)

Step 4: Match with Desired Colors

- Confirm that your chosen ribbon color can be produced in the particular grade you need since every grade does not offer all colors.

Ribbon Specifications to Consider

- Select a ribbon width that is equal to or greater than your label’s width.

- Roll Length: Affects downtime and change frequency

- The core size options for industrial printer ribbons usually include 0.5” and 1”, as well as 1” with notches depending on the printer model.

- The thermal transfer ribbon features the coating on the inside (CSI) or the outside (CSO).

Customizing Colored Thermal Transfer Ribbons

- Pantone color matching for brand consistency

- Thermal transfer ribbons can be tailored to meet the demands of quick production lines and specialized printing equipment.

- Special coatings for added resistance (e.g., UV-blocking)

- Distributors and OEM programs can benefit from packaging solutions under their private brand name.

Bulk Procurement Tips for B2B Buyers

1. Always Test Before Full Rollout

Request performance samples to test:

- Print quality

- Adhesion

- Resistance to smudging or abrasion

2. Verify Printer Compatibility

Provide supplier with:

- Printer model

- Printhead type (flat-head or near-edge)

- Ribbon width and winding requirements

3. Consider Storage Conditions

Colored resin ribbons can be sensitive to:

- High heat

- Moisture

- Place them in an environment that stays cool and free of moisture.

4. Forecast Usage for Better Pricing

Buying in bulk lowers the price per unit and keeps your stock levels steady.

5. Request Certifications

For industries requiring compliance:

- RoHS / REACH documentation

- FDA-grade contact compatibility

- GHS label support standards

Conclusion

Businesses in logistics and manufacturing benefit from color thermal transfer ribbons as they provide vibrant print alongside visual management support and regulatory compliance which strengthens branding.

Selecting the ideal ribbon formulation (wax, wax-resin, or resin) along with the best color for your application will enhance label clarity while minimizing mislabeling risks and boosting packaging professionalism.

📩 sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 https://foyottr.com

👉 [Contact Us Now](https: Visit our contact page to obtain professional guidance or arrange for a custom color ribbon quote that suits your business needs.

FAQs

Can color thermal transfer ribbons print barcodes?

Printing barcodes on thermal transfer ribbons works best with high-contrast colors such as black, dark blue, or red. However, scanner compatibility should be tested.

Are colored resin ribbons waterproof?

Yes, resin-based color ribbons offer excellent water, chemical, and abrasion resistance.

What’s the shelf life of color thermal transfer ribbons?

Typically 12–24 months when stored in a cool, dry place.

Can I use colored ribbons on any thermal label?

The label material must match the ribbon formulation. Resin ribbons require synthetic labels; wax can be used on paper.