Blog

Glossy Sticker Paper Wholesale Guide for Distributors and Buyers

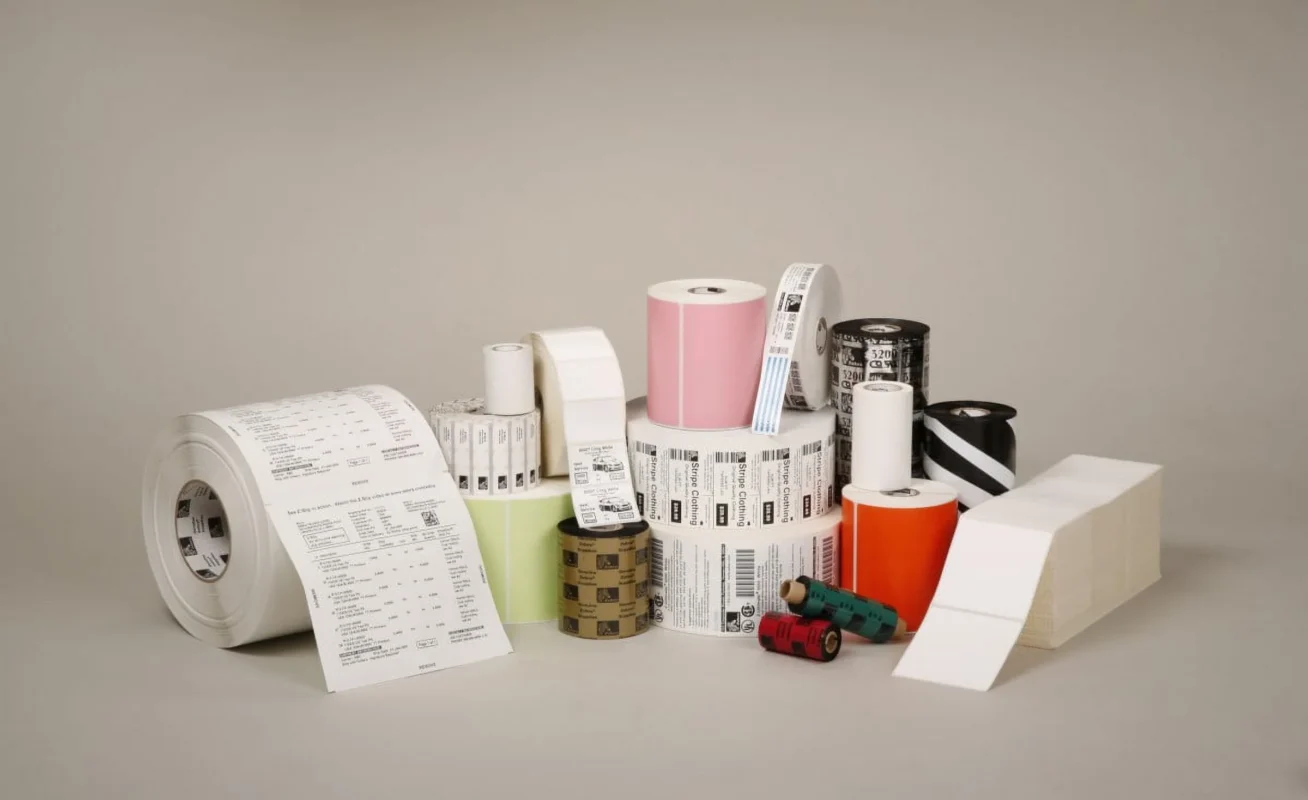

Businesses need glossy sticker paper to create high-quality and vibrant labels and stickers for their branding and marketing materials as well as packaging solutions. The professional finish and lustrous shine of this material makes it widely used across sectors including cosmetics and e-commerce to improve the visual appeal of logos and text.

B2B distributors, wholesalers and sourcing managers need to understand the different types of glossy sticker paper to meet client requirements and create value that leads to business growth. Bulk purchasers will find this comprehensive guide useful for understanding materials and finishes as well as adhesives and printing options together with procurement strategies.

What Is Glossy Sticker Paper?

Definition

Glossy sticker paper represents an adhesive-backed printable paper or film which has a smooth shiny surface that boosts color vibrancy and detail. The material works with inkjet, laser, or thermal transfer printing systems based on its coating and base material composition.

Main Features

- Reflective finish that makes colors pop

- Printable using inkjet or laser printers

- Water-resistant and scratch-resistant variants available

- Available in rolls or sheets

Types of Glossy Sticker Paper

Inkjet Glossy Sticker Paper

- Coated to absorb dye or pigment-based inks

- This sticker paper is best used for vibrant full-color designs along with professional logos and high-resolution photographs.

Laser Glossy Sticker Paper

- Heat-resistant coating for use with laser printers

- Produces sharp, smudge-free text and barcodes

Waterproof Glossy Sticker Paper

- This waterproof glossy sticker paper is manufactured from synthetic materials such as BOPP and vinyl.

- Suitable for outdoor, refrigerated, or high-humidity use

High-Gloss Finish

- Maximum shine and reflectivity

- Ideal printing solution for retail stickers and high-end product branding.

Semi-Gloss Finish

- Softer sheen with lower reflectivity

- This semi-gloss finish makes writing easy while being perfect for labeling product IDs and taking notes.

Materials Used

Paper-Based Glossy Sheets

- Most affordable

- Best for short-term indoor use

Vinyl

- Flexible and waterproof

- Great for bottles, jars, and curved packaging

Polypropylene (BOPP)

- Glossy, durable, oil- and water-resistant

- Ideal for food, cosmetic, and healthcare labeling

Polyester (PET)

- Highly durable and tear-resistant

- Often used for industrial and logistics labeling

Adhesive Options

Permanent Adhesive

- Long-lasting bond

- Used for product packaging, branding, and mailing

Removable Adhesive

- Allows clean removal without surface damage

- Common for temporary signage or promotional labels

Freezer-Grade Adhesive

- Withstands cold and moisture

- Essential for frozen foods and refrigerated goods

Printing Compatibility

Inkjet Printing

- Delivers rich, colorful designs

- This adhesive medium works well for producing photo stickers as well as crafting materials and custom labels.

Laser Printing

- Crisp text, smudge-proof output

- Laser printing provides clear text that is perfect for creating office documents as well as barcodes and product labels.

Thermal Transfer Printing

- Requires ribbons for long-lasting labels

- Used in warehousing, shipping, and industrial applications

Common Applications in B2B Use

Retail and E-Commerce

- Product labels, barcode stickers, promotional tags

- Personalized “Thank You” or logo stickers for product packaging

Food and Beverage

- Nutritional labels, ingredient stickers, expiration dates

- Oil- and moisture-resistant options available

Health and Beauty

- Clear and glossy cosmetic jar labels

- Waterproof and scratch-resistant for lotion, shampoo, etc.

Crafts and Stationery

- Use personalized planner stickers along with labels for notebooks and scrapbook pages.

Logistics and Manufacturing

- Inventory tracking, ID tags, and shipping labels

Customization Options for Distributors

Sizes and Shapes

- Standard sizes: 2”x2”, 4”x6”, A4, US Letter

- Custom die-cuts: circles, logos, product-specific shapes

Packaging Styles

- Bulk rolls with 1-inch or 3-inch cores along with sheet packs, polybags and white-label boxes represent various packaging options.

Surface Treatments

- The surface treatments available include UV gloss coating and anti-scratch laminates combined with writable matte gloss options.

Color and Branding

- CMYK or Pantone full-color printing

- Incorporate QR codes along with serial numbers and unique custom branding options.

Glossy sticker paper represents an intelligent choice for wholesale distributors.

Broad Market Reach

- Glossy sticker paper finds its application across multiple industries including retail, beauty, e-commerce along with logistic operations and event management.

High Repeat Order Potential

- Stickers are consumables—clients reorder frequently

OEM and Private Label Opportunities

- Clients can personalize packaging and branding for distribution within their local markets or across international boundaries.

Excellent Upsell Product

- These products work well when combined with printers and packaging supplies along with cutters.

Sourcing and Procurement Tips

Define End-Use Requirements

- Investigate which product types your clients require such as waterproof, writable, or removable variants

Match Material with Printing Type

- The material must operate effectively with inkjet printers as well as laser and thermal printing systems.

Request Samples

- Evaluate printability and adhesive strength along with durability testing before making large-scale orders.

Confirm MOQ and Lead Time

- MOQs usually span between 1,000 and 10,000 sheets or rolls.

- The usual lead time stands at 5 to 15 business days which varies based on the specific customization requested

Verify Quality Standards

- Ensure materials meet RoHS, REACH or food-grade standards where they are required.

Environmental Considerations

Sustainable Materials

- FSC-certified paper options available

- Biodegradable adhesives and low-VOC coatings upon request

Efficient Packing

- Roll and bulk options reduce shipping waste

- Green brands can receive packaging materials designed to be environmentally friendly.

Conclusion

Businesses around the world can meet their branding, packaging, and organizational needs with versatile glossy sticker paper which delivers high customer appeal. Its impressive appearance and extensive compatibility make it a beneficial product for distributors or resellers to include in their product selection.

B2B sellers who provide OEM options and customizable sizes and packaging formats while ensuring high-quality printing compatibility build lasting client relationships and secure repeat business in multiple sectors.

Frequently Asked Questions (FAQ)

Is glossy sticker paper waterproof?

Synthetic options such as BOPP or vinyl provide waterproof properties that regular paper lacks. Paper-based versions may not be unless coated.

Glossy sticker paper can be used with curved surfaces.

Yes. Printed labels made of vinyl and BOPP materials show good adhesion to curved bottles and jars.

What printers work with glossy sticker paper?

Select glossy paper based on your client’s printer type, whether it’s inkjet, laser, or thermal transfer.

Are custom die-cut shapes available?

Yes. Customers can fully customize die-cut shapes according to their logo designs and packaging needs.

Do you offer OEM and white-label packaging?

Absolutely. Our private label and OEM packaging services are designed to support brand growth.

Contact Us for Glossy Sticker Paper Solutions

Your company needs bulk glossy sticker paper alongside full customization support for its printing needs? We’re here to help.

📩 sales@foyottr.com

📞 Tel: +86-592-6018320

🌐 https://foyottr.com/

Visit our Contact Page to get started or request a quote today.