Blog

What Are Shipping Labels? A Complete Guide for B2B Logistics Buyers

Shipping labels function as key elements within modern logistics and eCommerce because they guarantee accurate delivery operations and provide supply chain traceability. The proper selection of shipping labels becomes vital for businesses that expand their operations because it affects operational performance as well as cost efficiency and customer satisfaction.

This guide serves distributors, purchasing managers, logistics coordinators, and sourcing agents who want to learn about shipping label structure and sourcing approaches for high-volume B2B operations.

What Are Shipping Labels?

Definition

Shipping labels consist of adhesive labels that attach to packages and display important delivery information. Shipping labels generally include the recipient address and return address along with a tracking number, barcode, and shipping method. Humans and automated systems such as barcode scanners and sortation robots read these labels.

Key Elements of a Shipping Label

- Sender and recipient address

- Barcode and tracking number

- Shipping service level (e.g., standard, express)

- Package weight and dimensions

- The shipping label displays the order ID along with SKU and batch number when relevant.

Print Technology Used

- Direct Thermal (most common for 4×6 labels)

- Thermal Transfer (for longer-lasting applications)

- Office setups and hybrid environments deploy both Laser and Inkjet printing technologies.

Why Shipping Labels Matter in B2B Logistics

- Make sure shipments arrive correctly by stopping misdirected deliveries and late arrivals

- Automation becomes possible when shipping labels work with scanners as well as WMS and ERP systems.

- Real-time order tracking across supply chains becomes possible with this feature.

- Streamline Returns: Include return instructions or barcodes

- Branding support through ready-made logos or QR codes on labels.

Shipping Label Sizes and Formats

| Label Size | Common Use | Printer Type |

|---|---|---|

| 4″ x 6″ | Standard shipping label | Desktop/industrial direct thermal |

| 4″ x 8″ | International/customs docs | Wide-format printers |

| 2″ x 1″ | Product, SKU or bin labels | Mobile/compact printers |

| 2.25″ x 1.25″ | Return address or inventory | Mobile thermal |

Types of Shipping Labels by Printing Method

Direct Thermal Labels

- No ribbon, ink, or toner required

- Short-term durability (6–12 months)

- Ideal for shipping, warehousing, eCommerce

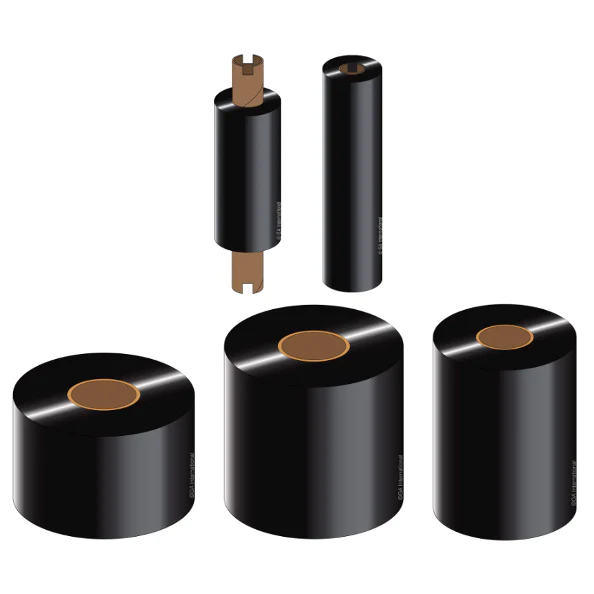

Thermal Transfer Labels

- A ribbon is necessary to apply ink to thermal transfer labels.

- Highly durable, moisture/heat/UV resistant

- Used in harsh or long-term storage environments

Inkjet and Laser Labels

- Used in office printers with sheet-fed formats

- Less efficient for high-volume logistics workflows

Core Components of a Shipping Label

Facestock

- Paper: Cost-effective, suitable for standard shipping

- Synthetic film (BOPP, PET): Water-resistant, tear-resistant

Adhesive

- This permanent adhesive maintains strong bonding capabilities on materials like cardboard, poly mailers, and shrink wrap.

- Removable: For reusable containers or temporary labeling

- Freezer-Grade: For cold storage or refrigerated logistics

Liner

- Backing paper with silicone coating enables simple peeling and feeding during label application.

- Available in rolls or fanfold formats

Applications of Shipping Labels

eCommerce

- Carrier-compatible labels (USPS, FedEx, UPS, etc.)

- Order tracking and return management

- Branded shipping and packaging

Warehousing & Distribution

- Pallet and bin labeling

- Inventory movement tracking

- Inter-departmental logistics

Healthcare & Pharma

- Prescription and sample shipment

- Lab and diagnostic kit labeling

- Cold chain logistics

Κατασκευή

- Batch number and part tracking

- Multi-product fulfillment labels

- Supplier-to-warehouse transfers

Printer Compatibility

Desktop Printers

- Ideal for mid-volume environments

- Desktop printers support label cores of 1” or 3” with a maximum width of 4”.

Industrial Printers

- Large batch jobs with fast print speeds

- Handles wider rolls, larger OD

Mobile Printers

- Lightweight, on-the-go printing

- Ideal for warehouses and field applications

How to Print Shipping Labels: Setup & Troubleshooting

Setup Steps

- Load label roll or fanfold stack

- Select proper label size (usually 4×6)

- Calibrate printer sensors

- Adjust print density and speed settings

Troubleshooting

- To fix faded print quality adjust the printer’s heat settings or switch to superior media.

- Skipping labels: Recalibrate gap sensor

- Adjust page size through software settings or modify guides to correct misalignment.

Comparing Label Formats: Roll vs Fanfold

| Format | Advantage | Use Case |

| Roll | Easy to load, compact | Desktop and industrial printers |

| Fanfold | High capacity, less downtime | Bulk warehouse printing |

Bulk Sourcing Shipping Labels: What to Consider

MOQ and Lead Times

- The minimum order quantity ranges from 10,000 labels to 100,000 labels based on given specifications.

- Lead time: 7–15 working days

Adhesive Selection

- Match surface: cardboard, plastic, cold packaging

- Consider temperature and humidity exposure

Roll Specs

- Core: 1” or 3”

- Industrial applications require rolls with an outer diameter that reaches a maximum of 8 inches.

- Winding direction: inside or outside wound

Customization Options

- Pre-printed logos, border frames, QR codes

- Labels for core applications and branding designs for outer carton packaging targeted to resellers

- Custom die-cut shapes and perforations

Quality Control

- Print clarity test (1D & 2D barcodes)

- Adhesion strength test on different substrates

- Die-cut tolerance and liner performance

Sustainability & Storage Guidelines

- Store in dry, cool conditions (15–25°C)

- Shelf life: 12–18 months from manufacture

- Recyclable paper-based options available

- Liner recycling possible with specialty programs

Conclusion

Shipping labels are fundamental to successful logistics and fulfillment processes. The performance and dependability of shipping labels have a direct effect on profit margins in warehouse operations, eCommerce businesses, and third-party logistics management.

The selection of appropriate material, adhesive, format, and supplier stands as a critical factor for B2B sourcing professionals and distributors who aim to preserve operational efficiency and customer satisfaction. With the appropriate label solution your packages remain trackable and scannable and reach their destination without mistakes.

Frequently Asked Questions (FAQ)

What’s the most common shipping label size?

4″ x 6″ is the industry standard for domestic and international shipping.

Can shipping labels be waterproof?

Only if made with synthetic film or a top-coated paper facestock.

Do I need thermal transfer or direct thermal?

Use direct thermal for short-term shipping; thermal transfer is better for long-term storage or harsh environments.

Are custom shipping labels available?

Yes. You can customize labels with pre-printed fields, logos, or QR codes.

What’s the lead time for bulk orders?

Typically 7–15 business days depending on volume and customization.

Looking for Reliable Shipping Labels in Bulk?

Contact us today to request samples, pricing, or discuss your requirements.

📧 Email: sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 Website: https://foyottr.com