ブログ

What Are Thermal Labels? An Introduction for B2B Buyers

Label printing fulfills essential operational roles in industrial, commercial and wholesale sectors by supporting product tracking, regulatory adherence, logistics management and customer satisfaction. Thermal printing stands out as one of the most effective labeling approaches because its operation depends on thermal labels.

Distributors, sourcing managers, label resellers, and manufacturers who understand thermal labels are able to make better procurement decisions which lead to improved operational efficiency and reduced expenses. This guide provides an overview of thermal labels and their different types before explaining their use cases and identifying essential factors to consider for bulk orders.

What Are Thermal Labels?

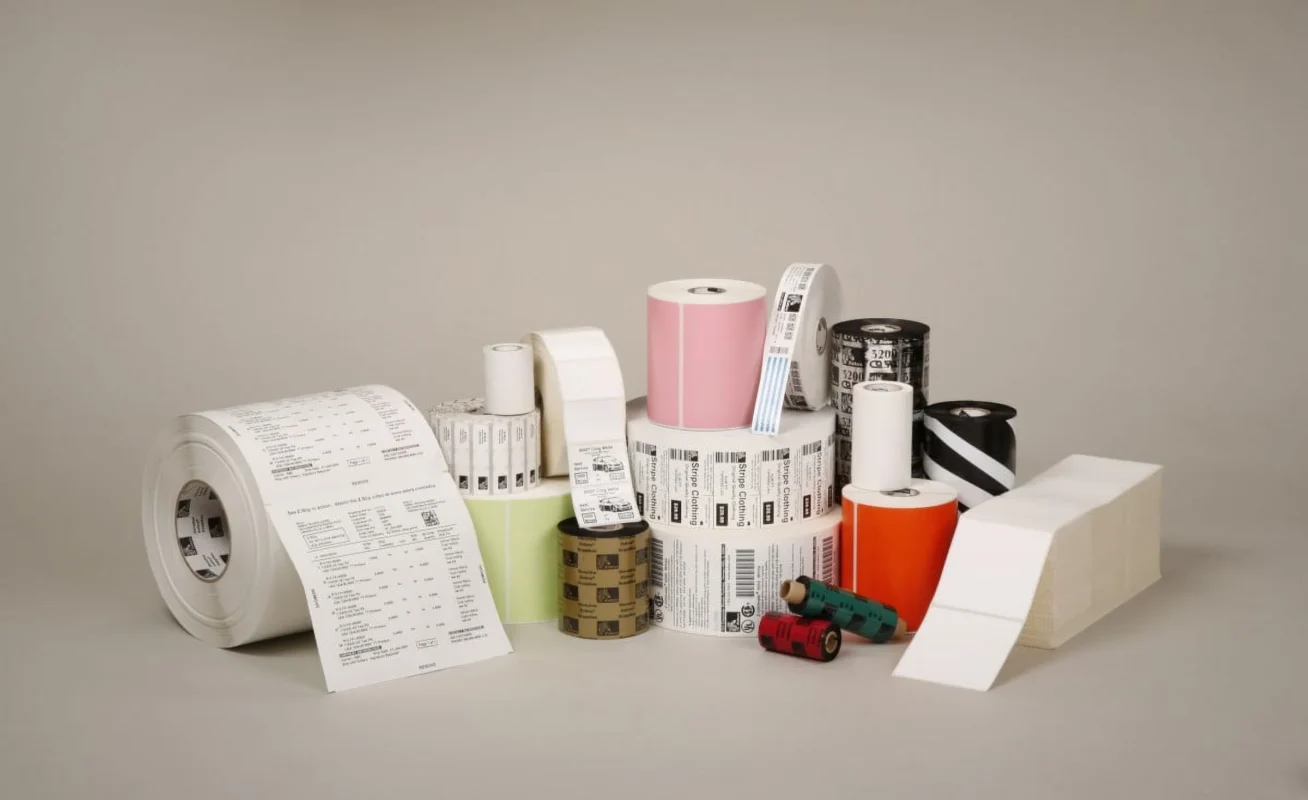

Thermal labels are unique labels that use heat for printing and eliminate the need for standard printing supplies like ink or toner. The printing of thermal labels involves thermal printers that employ either direct thermal or thermal transfer methods.

Core Characteristics:

- High-speed printing

- Clear barcodes and sharp text

- Thermal labels find applications across multiple sectors including logistics, healthcare, manufacturing, retail, and food production.

- These labels come in both roll and sheet forms which are usually tailored for industrial printing equipment.

Types of Thermal Labels

The classification of thermal labels depends on their specific printing technology.

1. Direct Thermal Labels

- Require no ribbon or ink

- Heat-sensitive coating on the label itself

- Cost-effective for short-term use

- These labels are appropriate for shipping labels, food packaging materials, and tickets.

2. Thermal Transfer Labels

- The thermal transfer printing method utilizes a ribbon to apply ink through heat transfer.

- These labels display durable prints that remain vivid against fading, moisture exposure and chemical contact.

- Thermal transfer labels serve as excellent solutions for asset tracking and inventory management while meeting regulatory labeling requirements

How Thermal Labels Work

Direct Thermal Printing

When exposed to heat from a thermal printhead a heat-sensitive label darkens predetermined areas to create text and images. This basic printing procedure is ideal for temporary label uses.

Thermal Transfer Printing

The ribbon receives heat which enables it to transfer ink onto the label surface. This printing method creates more robust labels that function on a range of materials including synthetics, films and foils.

Benefits of Thermal Labels for B2B Buyers

1. Fast and Reliable Printing

Thermal printers deliver rapid output with few moving components. It leads to decreased maintenance downtime while enabling faster fulfillment processes.

2. High-Quality Output

Clear barcode resolution enables quick and precise scanning which is critical for shipping operations as well as warehouse management and regulatory compliance.

3. Cost-Efficient Operations

Thermal printing minimizes consumables. Direct thermal labels eliminate the need for ribbons while thermal transfer ribbons demonstrate extended durability.

4. Compatibility with Automation

Auto-labeling machines and ERP/WMS systems operate effectively with thermal labels for seamless integration.

5. Wide Customization Range

- Custom sizes, die-cuts, and shapes

- Material options (paper, synthetic, polypropylene, etc.)

- Permanent, removable, or freezer-grade adhesives

6. Bulk Ordering Advantage

Bulk purchases help lower unit costs while minimizing shipping needs and saving administrative hours which makes it perfect for business-to-business label acquisition.

Common Applications of Thermal Labels

Logistics and Shipping

- Box and pallet labels

- Courier waybills

- Tracking barcodes

Retail and E-commerce

- Price tags

- Inventory SKUs

- Packaging seals

Food Industry

- Fresh food date labels

- Nutritional facts

- Cold storage inventory

Manufacturing and Warehousing

- Internal traceability tags

- Assembly line labeling

- Barcode-based inventory control

Healthcare and Pharmaceuticals

- Lab vial labels

- Prescription packaging

- Patient wristbands

This section discusses selecting the appropriate thermal label for different needs.

Consider Your Application Environment

- Direct thermal for dry, short-term use

- Thermal transfer technology provides labels that maintain legibility throughout long-term outdoor exposure.

Determine Print Longevity Requirements

Thermal transfer printing should be used when labels need to maintain readability for extended periods of months or years.

Define Label Size and Format

Select label dimensions that match your product packaging requirements along with print alignment and storage needs.

Select the Right Adhesive

- Permanent: for shipping, asset tagging

- Removable: for temporary labeling

- Freezer-safe: for cold storage and food service

Customizing Thermal Labels for Business Operations

Roll Specifications

- Core diameter (1” or 3”)

- Outer roll diameter (4” to 8”)

- Winding direction (inside or outside)

Pre-Printed Zones

- Add logos, color codes, or safety icons

- Maintain brand consistency across product lines

Coatings and Finishes

- Gloss or matte finishes

- Topcoats protect against moisture and oil damage as well as UV light exposure.

Serialization and Variable Data

- Create traceability labels by printing batch codes along with serial numbers and QR codes or regulatory symbols

Why B2B Buyers Prefer Thermal Labels

- Scalability: Handles large volumes efficiently

- Thermal labels demonstrate adaptability across various industries and multiple regulatory requirements.

- The product connects with enterprise resource planning systems along with shipping solutions and inventory management tools.

- Accelerates labeling processes for automated production lines

Bulk Procurement Tips

- Running tests on adhesives, materials, and print quality using your actual application before making a purchase ensures product suitability.

- Your equipment must be able to print labels that meet specifications including core size, label width, and sensor marks.

- Calculate how much product you need each month or quarter to benefit from bulk pricing and ensure supply stability.

- Establish quality expectations through specification of material weight (such as 80gsm) as well as the liner type and adhesive strength.

- When working with regulated sectors require companies to show their compliance documentation.

- RoHS / REACH conformity

- FDA-compliant adhesives (for food contact)

- Chemical resistance (for pharma or lab use)

Conclusion

Thermal labels form the foundation of labeling strategies in industrial applications. The proper selection of thermal labels affects your business operations efficiency and regulatory compliance while maintaining brand quality whether you print shipping labels in bulk or track pharmaceutical products with serialization.

When you learn to differentiate direct thermal from thermal transfer labels and adjust label materials and adhesives accordingly you achieve best results throughout your labeling operation.

📩 sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 https://foyottr.com

👉 Contact Us Now to explore thermal label solutions tailored to your operation.

FAQs

What’s the main difference between direct thermal and thermal transfer labels?

Direct thermal labels require no ribbon and are suited for short-term use. Thermal transfer labels use a ribbon for more durable and long-lasting prints.

Can thermal labels be used in cold storage?

Yes, with the appropriate adhesive. Freezer-grade adhesives ensure the labels remain intact in cold or frozen environments.

Are thermal labels eco-friendly?

Yes. Many are recyclable and produce less waste, especially direct thermal labels that use no ribbons or ink.

How long do thermal labels last?

Direct thermal labels last a few weeks to a few months. Thermal transfer labels can last years depending on the environment and material.

Do you offer custom sizes and pre-printing services?

Yes. Custom thermal labels can be made in any shape, size, or adhesive type, and can include logos, regulatory symbols, and color zones for branding or compliance.