Blog

Label Maker Paper: The Ultimate Guide for Distributors and Procurement Managers

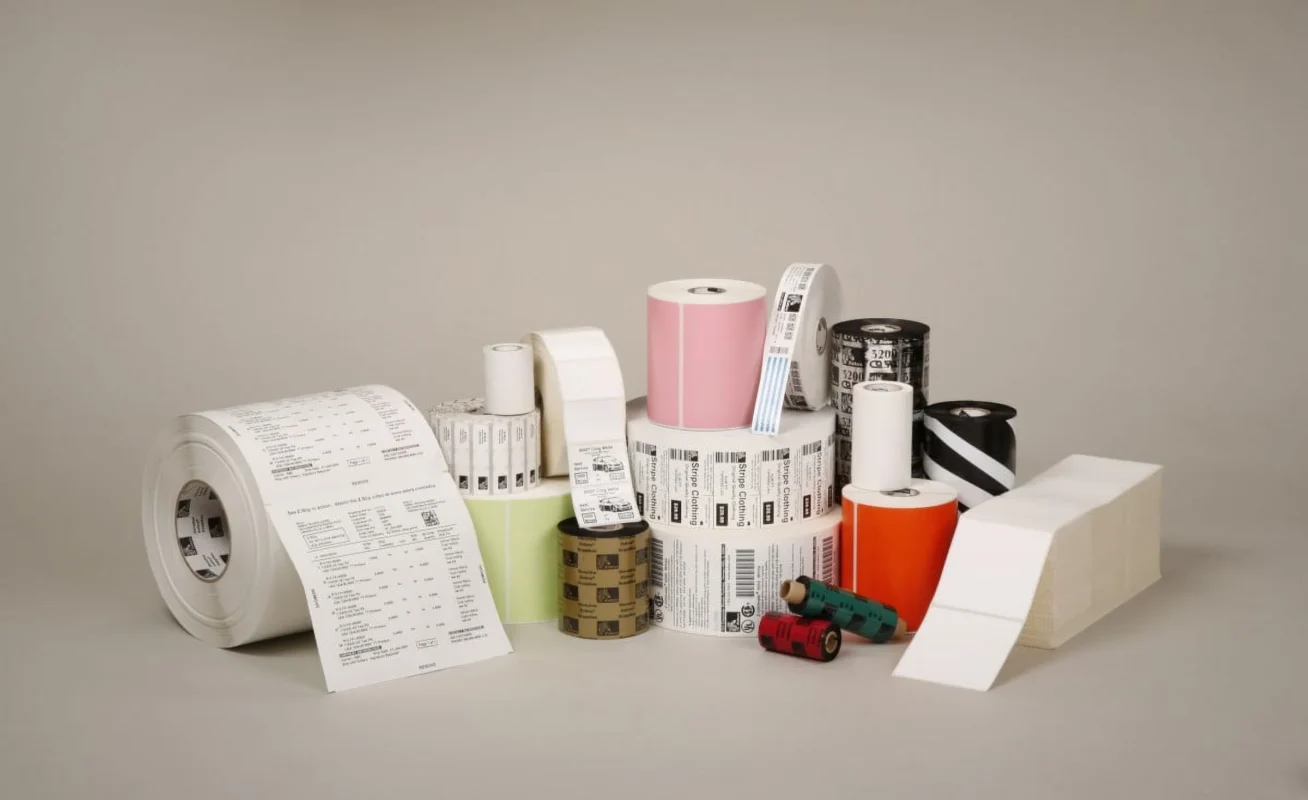

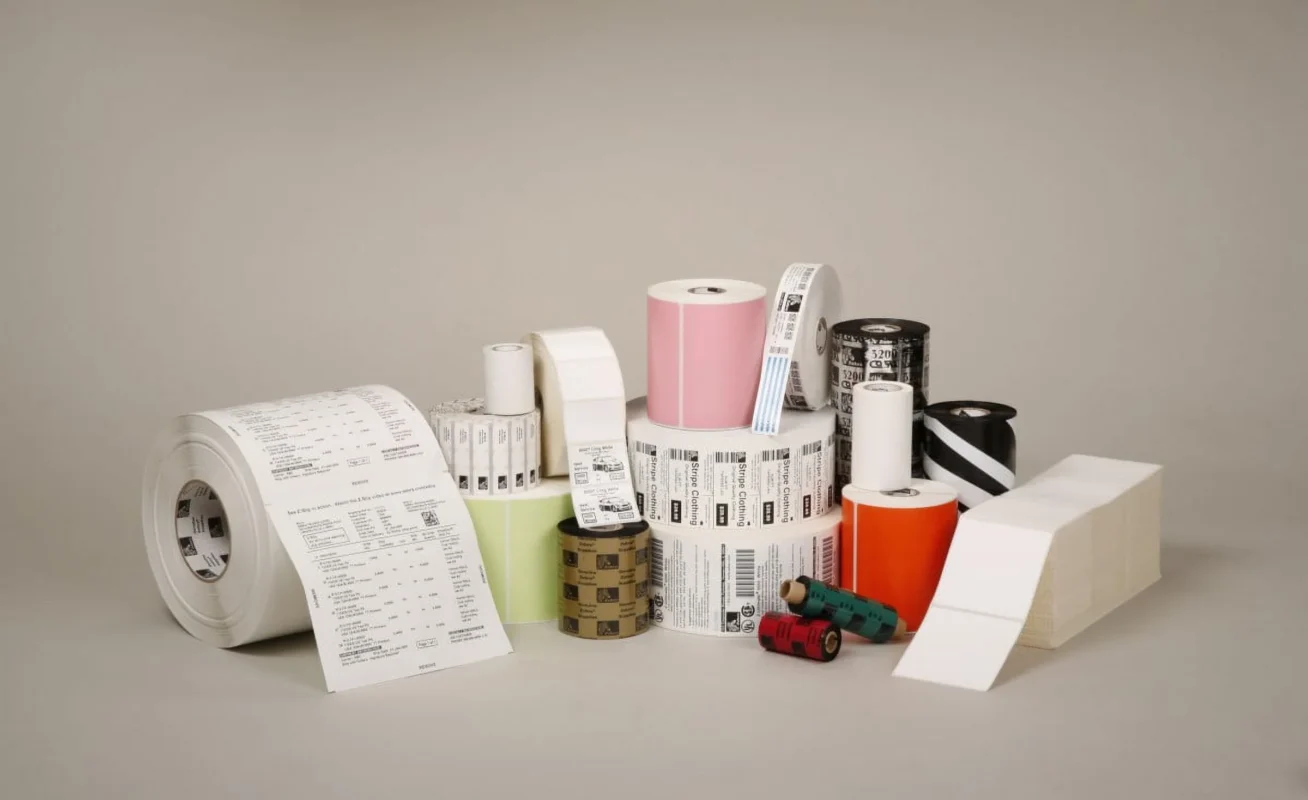

The process of labeling serves essential purposes across logistics operations as well as inventory management and extends to both retail and manufacturing sectors. Label maker paper determines print clarity standards and maintains durability together with adhesive strength during label creation. Distributors and procurement professionals need to understand label maker paper to maintain quality standards and ensure compatibility with devices while securing reliable supply chains.

This complete guide examines the different kinds of label maker paper materials and their applications while providing essential tips for sourcing. This article gives bulk buyers and B2B professionals the resources they need to make well-informed purchasing choices.

What is Label Maker Paper?

Label maker paper consists of adhesive-backed paper rolls or sheets designed to work with label printers and handheld label makers. Users print on these papers with thermal or ink methods before applying them to different surfaces where they remain attached securely for identification and tracking.

Label maker paper contains three distinct layers for printing and adhesion.

- The printable surface of the top layer known as facestock could be made of paper or synthetic material.

- The adhesive layer consists of pressure-sensitive glue which attaches to surfaces.

- The backing liner consists of a silicone coating that guards the adhesive during storage.

Types of Label Maker Paper

1. Direct Thermal Paper

- No ribbon or ink required

- Heat-sensitive coating reacts to printhead

- This labeling paper works best for temporary uses such as shipping labels and price tags.

2. Thermal Transfer Paper

- Requires a ribbon to transfer ink

- Offers long-lasting durability and high resistance

- Common in manufacturing and industrial labeling

3. Matte Paper Labels

- Cost-effective

- Compatible with most ink and laser printers

- Ideal for internal use and document organization

4. Glossy Paper Labels

- High-shine finish for premium appearance

- Used in cosmetics, retail, and packaging

5. Synthetic Label Paper

- The label paper consists of materials including polypropylene (PP), polyester (PET), and vinyl.

- Tear-resistant, waterproof, and chemical-resistant

Sizes and Specifications

The widths, lengths, and die-cut shapes of label maker paper differ to ensure compatibility with various machines and their specific applications.

Common Widths:

- 6mm, 9mm, 12mm, 19mm, 24mm, 36mm

Core Sizes:

- 0.5-inch, 1-inch, and 3-inch cores

Roll Length:

- The roll length varies between 4 meters and 100 meters based on the specific type and its intended use.

Adhesive Types:

- Permanent: Strong adhesion for long-term labeling

- Removable: Peels off cleanly without residue

- Freezer-grade materials work well with cold storage applications and frozen products.

Material Comparison Table

| Material Type | Durability | Moisture Resistance | Chemical Resistance | Ideal Use |

|---|---|---|---|---|

| Paper | Moderate | Low | Low | Office, retail |

| PP (Polypropylene) | High | Medium | Medium | Packaging, bottles |

| PET (Polyester) | Very High | High | High | Industrial, outdoor |

| Vinyl | High | Very High | High | Cable/wire labeling |

Industry Applications

1. Retail and Supermarkets

- Price labels

- Barcode tags

- Product identifiers

2. Logistics and Warehousing

- Shipping labels

- Bin identifiers

- Inventory management tags

3. Manufacturing

- Batch and serial number labels

- Quality control tags

- Hazard identification

4. Healthcare and Laboratory

- Sample labels

- Prescription tags

- ID wristbands

5. Office and Admin

- File organization

- Cable tags

- Folder and shelf labels

Advantages for Distributors

High Volume Demand

Label maker paper functions as a consumable merchandise that requires ongoing purchase cycles.

Customization Opportunities

We provide clients with branded packaging options alongside custom label sizes and pre-printed solutions.

Profitability

Bulk resellers find high margin opportunities through cost-effective production methods.

Compatibility Versatility

The product is compatible with thermal and ink-based machines which boosts product variety.

Select label maker paper that fits the specific label maker models used by your clients based on size, roll type, and material specifications.

1. Printer Compatibility

Select label maker paper that aligns with your client’s model specifications regarding size, roll type, and material.

2. Print Quality

Test for smudge-proof, fade-resistant, and high-resolution printing.

3. Adhesive Strength

Ensure adhesive types (permanent or removable) correspond to their specific application needs.

4. Durability

Select materials that can withstand water exposure or chemical contact when working on outdoor or industrial projects.

5. Packaging and Labeling

Bulk buyers may request:

- White box or neutral packaging

- Private label branding

- Custom barcode or SKU printing

6. Certification and Compliance

Verify product adherence to RoHS, REACH regulations, and FSC standards when paper usage applies.

7. MOQ and Lead Times

Create production timelines with low minimum requirements to assist smaller distributors and accommodate trial orders.

Why Choose FOYO for Label Maker Paper?

FOYO operates as a principal division within FUYOU Group with more than 15 years of expertise in creating label products and conducting research and development. Our production process combines coating and slitting with OEM packaging to maintain high-quality standards while achieving fast delivery and competitive pricing.

FOYO Capabilities:

- FOYO supplies both thermal and synthetic label papers in numerous varieties.

- Customized roll sizes, adhesives, and finishes

- Flexible MOQ for distributors

- Private label support

- Strict quality control and global export experience

Conclusion

The basic appearance of label maker paper hides its crucial role in printing performance and label longevity while determining user satisfaction. B2B buyers who match paper types to specific printers and end-use scenarios will see increased sales and improved brand trust.

Working with FOYO gives you premium label paper that complies with industrial standards and offers customizable options while delivering strong bulk distribution margins.

FAQ

Label maker paper maintains its quality for 12 to 24 months if stored in environments that are cool and dry.

Label maker paper has a shelf life of up to 12 to 24 months when stored under cool and dry conditions.

Can label maker paper be customized?

Yes. FOYO enables OEM adjustments of paper width and length as well as core size and adhesive type with packaging options.

Our label papers work with the majority of major label maker models.

We provide thermal and inkjet-compatible label papers which work with almost all major label machine models.

Are there eco-friendly label paper options?

Customers can request FSC-certified paper which is recyclable for label printing.

Fulfillment time for bulk orders varies between 15 and 25 business days based on order volume and specific customization needs.

The order fulfillment time range for bulk orders is 15 to 25 business days based on order volume and specific customization needs.

Contact Us

📩 sales@foyottr.com

📞 Tel: +86-592-6018320

🌐 https://foyottr.com/

Visit our Contact Page to get started or request a quote today.