Blog

Printer Label Printer: Your Guide to Efficient Labeling Solutions

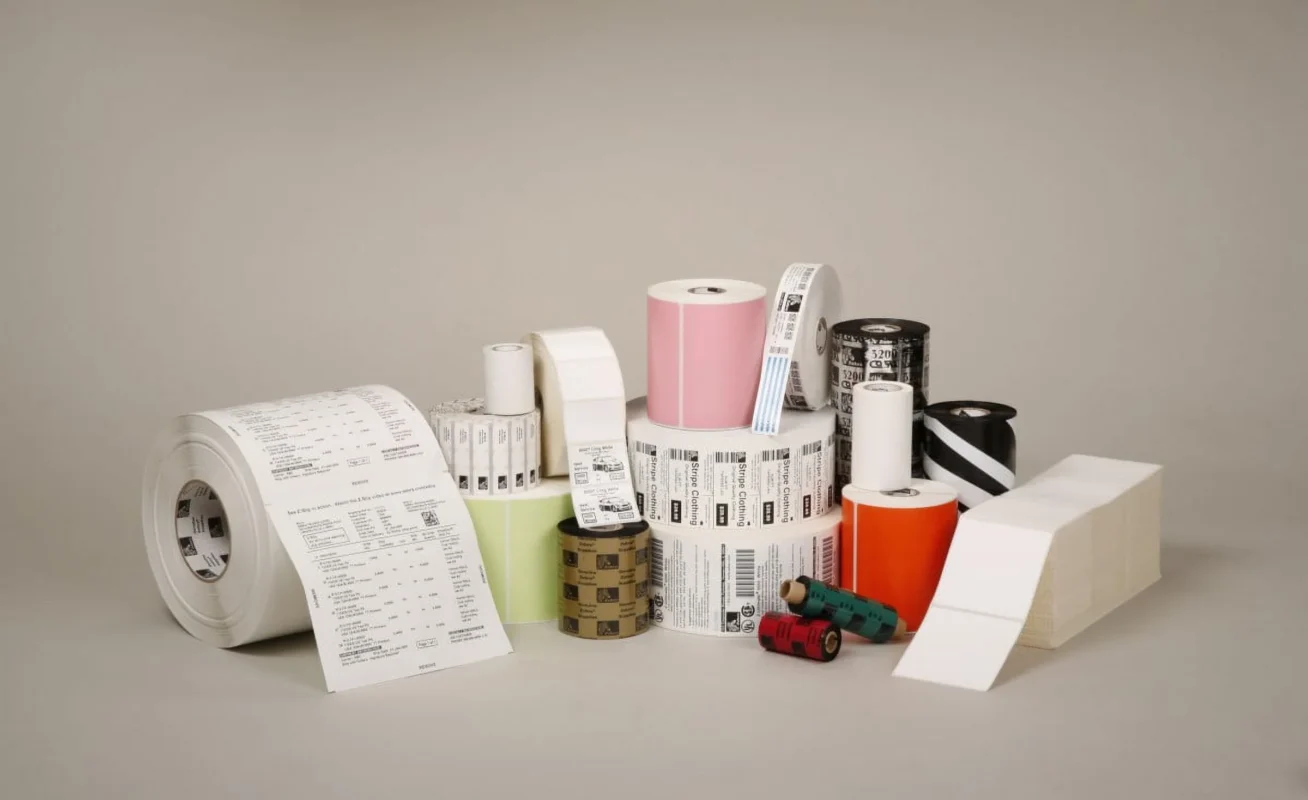

The commercial world today demands that labeling processes be efficient and accurate without exception. A reliable printer label printer helps streamline operations for warehouses, retail chains, manufacturing plants, and logistics businesses. This guide thoroughly covers the essential aspects of selecting and operating label printers meant for professional use.

What is a Printer Label Printer?

A printer label printer functions as a specialized machine that produces self-adhesive labels for multiple purposes including shipping processes and inventory control. Printers operate with either thermal transfer or direct thermal printing technologies to produce labels that differ in quality level, printing speed, and longevity.

Types of Label Printers

1. Direct Thermal Label Printers

- Ideal for short-term labeling.

- No ink or ribbon required.

- Suitable for shipping labels and temporary barcodes.

2. Thermal Transfer Label Printers

- Uses a ribbon to print durable labels.

- Resistant to heat, chemicals, and abrasion.

- Common in industrial, chemical, and pharmaceutical applications.

3. Inkjet Label Printers

- Provides high-quality color printing.

- These printers serve well for product labels while also meeting the needs of craft businesses and packaging requirements.

4. Laser Label Printers

- Good for high-volume printing.

- Offers sharp text and images.

- Cost-effective for bulk printing jobs.

Key Features to Consider

1. Print Resolution

- Measured in DPI (dots per inch).

- A greater DPI count delivers improved image sharpness along with better barcode scanning ability.

2. Print Speed

- Speed is essential for high-demand operations.

- The printing speed of industrial models reaches up to 14 inches per second.

3. Connectivity

- USB, Ethernet, Wi-Fi, and Bluetooth options.

- Your network requirements and mobility needs should guide your printer connectivity choice.

4. Label Compatibility

- The printer must be able to work with various label dimensions and different materials.

5. Durability and Build Quality

- Industrial-grade printers feature design features that enable them to endure challenging environments.

Applications of Printer Label Printers

- Warehouse Management: Inventory tags, location labels.

- Retail: Price tags, shelf labels, promotional stickers.

- Healthcare: Patient ID bands, specimen labels.

- Logistics: Shipping labels, tracking barcodes.

- Manufacturing: Product identification, safety labels.

Benefits for Distributors and Purchasing Managers

- Bulk Efficiency: High-volume printing for mass labeling.

- Purchasing labels in large rolls helps achieve cost savings per unit.

- Users can modify labels because these products support different sizes and styles.

- Scalability: Easily integrated into existing production lines.

Selecting the optimal label printer involves understanding your business requirements and matching them to printer specifications.

Step 1: Identify Your Application Needs

- Consider the environment (office, warehouse, outdoors).

- Evaluate print durability requirements.

Step 2: Determine Label Volume

- Small operations: Desktop printers.

- Large-scale: Industrial-grade machines.

Step 3: Check Software Compatibility

- Confirm that your printer functions with both label design software and ERP systems.

Step 4: Choose the Right Supplier

- Collaborate with reliable manufacturers who provide after-sales support alongside OEM/ODM services.

Why Wholesale Buyers Trust FOYO

FOYO stands as a seasoned provider in thermal label solutions with more than ten years of professional experience.

- Competitive factory pricing

- Full OEM & ODM customization

- High-quality thermal ribbons and label supplies

- Global logistics support

Conclusion

Investing in a high-quality printer label printer yields benefits beyond basic functionality as it enhances efficiency and accuracy while supporting business scalability. The correct label printer selection will enhance your operational workflow whether you are labeling products or organizing inventory and maintaining compliance. Trusted manufacturers like FOYO produce industrial-grade label printers that deliver significant advantages for distributors, resellers, and bulk buyers.

FAQ

Q1: Industrial label printers typically operate for 5 to 10 years when they receive proper maintenance.

A: With proper maintenance industrial label printers will remain operational for 5 to 10 years.

Q2: Is it possible to print both barcode and color labels with a single printer?

A: Color labels require inkjet printers as the appropriate printing solution. Thermal printers function best when producing barcodes and text documents.

Q3: Do you provide bulk label printer supplies?

A: FOYO supplies wholesale labels alongside ribbons and other necessary consumables for every printer model.

Q4: Can I personalize the label printer to include my company’s logo?

A: FOYO provides comprehensive OEM/ODM services to customers worldwide.

Q5: How do I maintain a thermal printer?

A: Maintaining a thermal printer requires consistent printhead cleaning alongside the use of compatible ribbons and labels to avoid damage.

Contact Us

📩 sales@foyottr.com

📞 Tel: +86-592-6018320

🌐 https://foyottr.com/

Visit our Contact Page to get started or request a quote today.