Blog

Mailing Label Maker: A Complete Guide for Distributors and Resellers

Modern logistics and fulfillment operations require both speed and precision to function effectively. No matter if you operate a warehouse or handle e-commerce logistics or retail packaging solutions mailing label makers become indispensable tools which enhance operational efficiency. The article provides distributors, resellers, and procurement professionals with complete knowledge about mailing label makers including their functions, procurement tips, types along with integration methods for existing logistics systems.

What is a Mailing Label Maker?

Mailing label makers are systems that create shipping and address labels for parcels through device or software means. Most mailing label makers print labels in formats that postal services and major courier companies can accept. A suitable label maker minimizes human mistakes while accelerating packaging and sustaining smooth shipping operations.

Core Functions

- The address printing function displays the sender and receiver details clearly on the label.

- Enable barcode production to facilitate inventory management and tracking procedures.

- Businesses can utilize their company’s specific branding elements by incorporating logos and unique layout designs in custom templates.

- Batch Printing lets users produce hundreds of labels simultaneously.

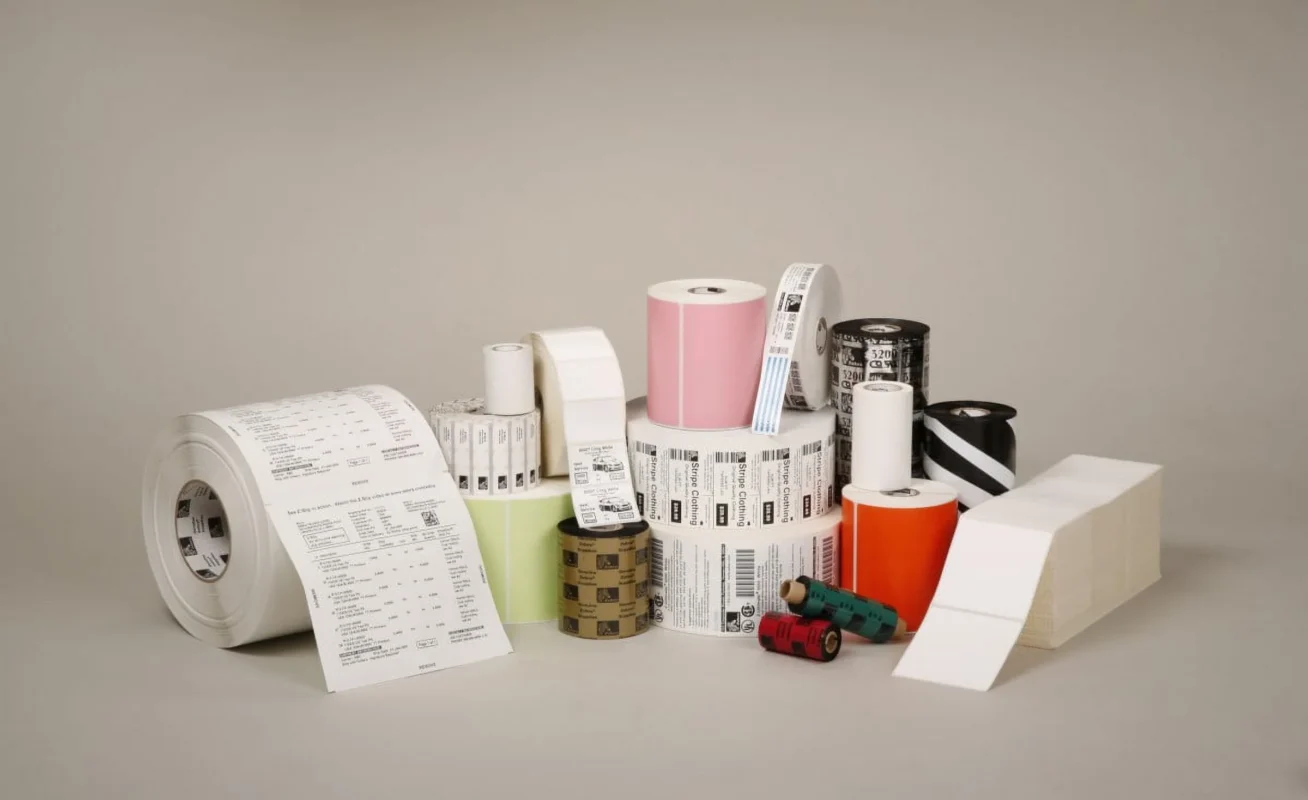

Types of Mailing Label Makers

Your operation requires choosing an appropriate label maker that fits its specific needs.

1. Thermal Label Makers

Thermal label machines produce labels through heating processes which makes them ideal for environments with heavy shipping demands.

2. Inkjet/Laser Label Makers

Inkjet/Laser Label Makers serve small businesses with limited print demands and enable vibrant and personalized label creation.

3. Portable Label Printers

Portable label printers provide essential support for field logistics operations and mobile workstations and are especially important in warehouses that require adaptable solutions.

Benefits for Distributors and Procurement Teams

1. Enhanced Productivity

Quick printing technology results in accelerated order processing times and improved throughput efficiency.

2. Reduced Errors

The automation of address imports and barcode printing leads to fewer manual errors.

3. Cost Efficiency

Printing labels in bulk lowers the price for each label while also eliminating excess material usage.

4. Seamless Integration

The latest mailing label makers provide integration capabilities with ERP systems along with CRM and inventory management platforms.

Features to Look For When Sourcing

1. Print Speed and Resolution

Verify that your selection matches both your required production volume and quality benchmarks.

2. Connectivity Options

Your setup requires compatibility with USB, Ethernet, Wi-Fi, or Bluetooth connectivity.

3. Label Compatibility

Verify whether the label maker supports both the dimensions and label type that your operation requires.

4. Software Support

Test that the drivers work with your software and integrate seamlessly into your existing work processes.

Industry Applications

E-commerce Fulfillment Centers

High-speed printing and automation are critical.

Logistics and Shipping Warehouses

Bulk label makers help streamline outbound shipments.

Retail Distribution

Facilitates inventory management and delivery labeling.

Manufacturing Supply Chains

The system provides instantaneous label printing solutions for both packing processes and quality control checks.

Tips for Bulk Purchasing

- Before committing to any bulk label orders make sure to test both the adhesion and clarity of samples.

- Analyse supplier options by looking at their pricing structure, lead time period, and the quality of their technical support.

- Long-term service agreements play a critical role in warranty and support assessments.

- Combine your label rolls and ribbons into a single shipment to achieve shipping cost savings.

Conclusion

Distributors and procurement professionals who manage large shipments need mailing label makers as essential tools. Selecting the right device can improve efficiency while reducing costs and streamlining your logistics operations.

Choosing a dependable manufacturer for your business’s label makers will help you build value that lasts. Contact our experts now to learn about our wholesale solutions.

Contact Us

📧 sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 https://foyottr.com/

FAQ

Most couriers accept the standard 4×6 inch label which makes it the optimal choice for mailing purposes.

Most couriers accept the standard 4×6 inch label which makes it the preferred choice for mailing and shipping.

Multiple mailing label makers offer integration options with warehouse management systems through APIs and drivers.

Several label-making models are compatible with API or driver-level integration to support WMS systems as well as ERP and CRM platforms.

Thermal printers offer significant advantages over inkjet printers for high-volume shipping because of their speed and reduced maintenance needs.

Thermal printers prove ideal for high-volume shipping tasks because they operate quickly while needing minimal upkeep and demonstrating strong durability.

Can I print custom branded labels?

Yes. The majority of software solutions enable users to load logos and create branded templates through their systems.

Lead time for bulk label maker shipments depends on order size and customization but typically ships within 7–15 business days.

The delivery time for bulk orders depends on the order size and level of customization but usually ships within 7 to 15 business days.

Contact Us

📩 sales@foyottr.com

📞 Tel: +86-592-6018320

🌐 https://foyottr.com/

Visit our Contact Page to get started or request a quote today.