Blog

What Are Beverage Labels and Why Do They Matter in Branding and Compliance?

The beverage industry’s competitive environment requires packaging solutions that guide consumer decision-making while meeting regulatory standards. Beverage labels form the core element of effective packaging strategies because they represent brand identity while delivering essential product details like flavor components and nutritional information alongside legal requirements.

The design of beverage labels requires both visual appeal and functionality across all types of drinks including water bottles, energy drinks, wine and juices as well as dairy products. Distributors and sourcing managers alongside OEM partners need to comprehend beverage labels’ technical and marketing functions to provide value to their end clients.

The article analyzes how beverage labels are structured and function along with their material composition while also detailing customization possibilities and bulk sourcing methods for B2B applications.

What Are Beverage Labels?

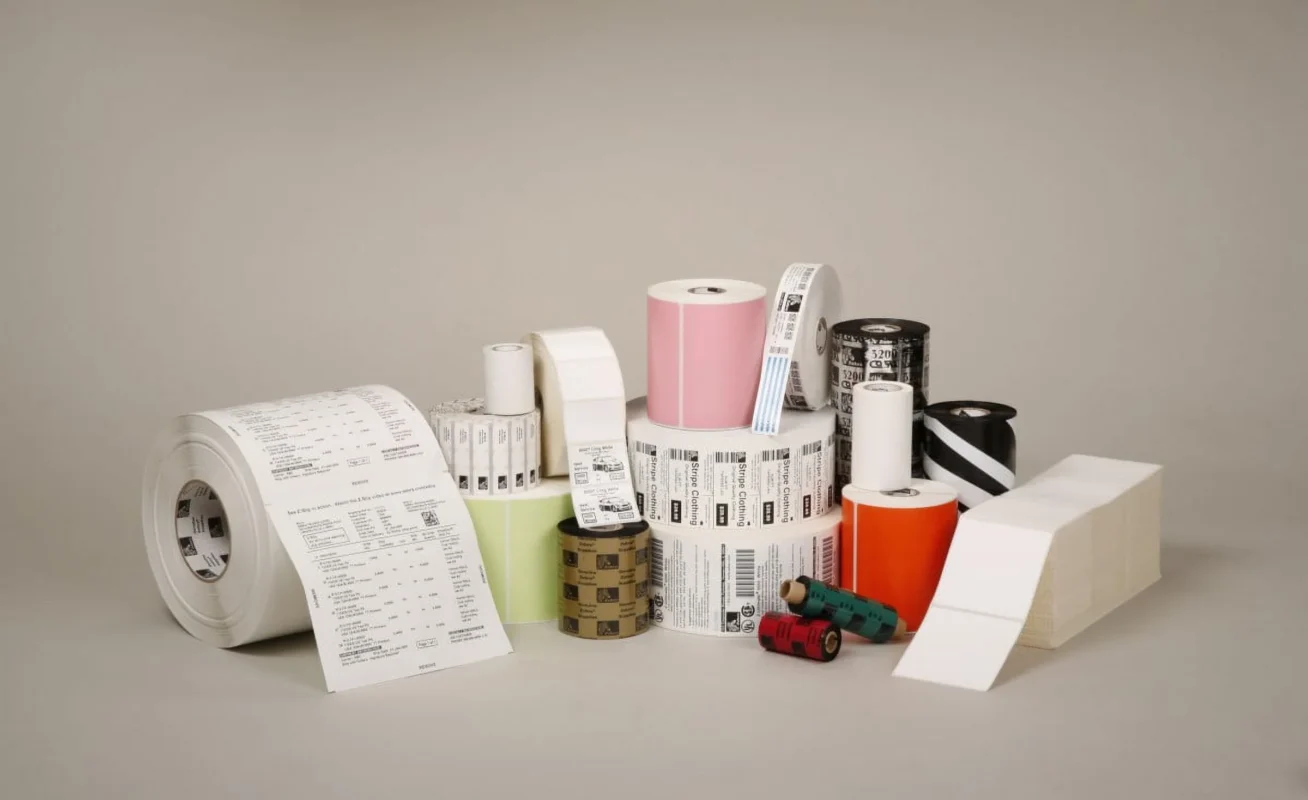

Beverage labels refer to adhesive stickers that attach to bottles, cans, pouches, or cartons to convey brand identity along with mandatory legal details and essential product information. Manufacturers produce beverage labels on roll or sheet formats which allows businesses to modify their size, shape, finish, and adhesive properties based on container needs and beverage specifications.

These labels serve several critical functions:

- Branding: Communicate brand identity and visual appeal

- Consumer Information: Ingredients, nutritional facts, usage directions

- The compliance labels include legal warnings and barcodes along with manufacturing and expiration dates.

- Logistics tracking systems and batch codes combined with QR codes make up traceability measures.

Common Types of Beverage Labels

1. Pressure-Sensitive Labels (PSL)

- Self-adhesive and ready to apply

- Compatible with a wide range of materials

- Ideal for bottles, cans, and curved surfaces

2. Wrap-Around Labels

- Applied 360° around cylindrical containers

- Bottled water and soft drinks typically use wrap-around labels.

3. Shrink Sleeve Labels

- Heat-shrinked to contour-fit complex shapes

- Excellent for full-color branding and tamper evidence

4. Cut-and-Stack Labels

- Economical option for high-speed bottling

- Requires glue during application

5. In-Mold Labels (IML)

- Fused with plastic containers during molding

- Durable and tamper-resistant

Materials Used in Beverage Labeling

| Material Type | Best For |

|---|---|

| Gloss Paper | Juices, dairy, promotional drinks |

| Matte Paper | Writable applications, eco-friendly look |

| Polypropylene (BOPP) | Cold drinks, water bottles, condensation |

| PET (Polyester) | Energy drinks, glass bottles, freezer-safe |

| Vinyl | Long-term outdoor drinks and iced beverages |

| Clear Film | Premium/luxury branding on glass containers |

Adhesive Options

- Permanent adhesive options provide durable labeling solutions for plastic, glass, and metal surfaces.

- Removable: For promotional or temporary uses

- Freezer-grade: Maintains adhesion in sub-zero temperatures

- Wet-apply Adhesives: Designed for high-moisture bottling environments

Beverage Categories and Labeling Considerations

1. Bottled Water

- Transparent or minimal design

- Must withstand condensation

2. Carbonated Soft Drinks

- High-tack adhesive to resist pressure buildup

- Bright colors and full-wrap visuals

3. Alcoholic Beverages (Beer, Wine, Spirits)

- Compliance with alcohol labeling laws

- Shelf appeal for alcoholic beverages can be enhanced by using embossed labels together with foil and clear labeling options.

4. Juices and Smoothies

- Laminate protection from leaks or oils

- Bright, vibrant brand imagery

5. Energy Drinks

- Metallic inks, glossy finish

- High durability for active lifestyle branding

6. Milk and Dairy Beverages

- Labels resistant to moisture and refrigeration

- Simple, food-safe adhesives

Label Shapes and Sizes

- Rectangular shapes serve as the primary design standard for most beverage bottles and packaging cartons.

- Caps and front branding spaces require oval and circular label shapes.

- Die-cut shapes: Unique packaging appeal

- Full wrap-around: 360° coverage for promotional beverages

Printing Methods for Beverage Labels

| Method | Use Case |

| Flexographic | High-speed, large-volume runs |

| Digital | Short runs, frequent design changes |

| Thermal Transfer | On-site coding of batch/expiry |

| Screen Printing | Specialty effects like raised ink or textures |

Customization Options

- Finishes: Matte, gloss, soft-touch, clear, embossed

- Foil stamping: Gold, silver, or holographic accents

- Spot varnish: Targeted shine or texture

- Transparent window labels serve as excellent options for displaying clear liquids or showcasing products.

- Variable data printing allows for the customization of labels with batch numbers, QR codes, and multiple language options.

Label Compliance and Regulations

- Nutrition Labeling: FDA, EU, or country-specific requirements

- Labels for alcoholic products must include warnings that comply with TTB guidelines and national regulations.

- Following UPC, EAN, or GS1 standards ensures barcode and traceability.

- Allergen Disclosure: Must be clear and legible

- Environmental Claims: Recyclable, biodegradable indicators

Bulk Procurement Guide for Beverage Labels

1. Define Application Needs

- Considerations for label specification include the label dimensions along with container geometry and moisture protection requirements and machine compatibility.

2. Choose the Right Material and Finish

- Cold-fill or hot-fill? Freezer-safe? Food-contact grade?

3. Verify Roll Specs for Machinery

- The roll must be measured for width and core diameter options of 1” or 3” alongside unwind direction and label spacing.

4. Request Proofs and Samples

- Evaluate the adhesive strength of labels along with their print quality and surface compatibility.

5. Order in Economical Batches

- Typical MOQs: 5,000–50,000+ labels depending on spec

- Bulk discounts available for larger production runs

6. Consider Private Label Packaging

- OEM solutions provide packaging options that feature either generic packaging or custom client branding on the outer packaging.

7. Ensure Certifications and Safety Compliance

- Products must meet RoHS, REACH, ISO 9001 standards and obtain FDA approval for indirect food contact.

Conclusion

Beverage labels function as more than just decorative features on containers. Beverage labels serve as functional assets that enhance brand visibility while maintaining legal compliance and providing consumer information. The selection of label type, adhesive, and design finish becomes a critical factor for shelf success when labeling products like bottled water, wine, or protein smoothies.

B2B purchasers benefit from working with reliable label manufacturers who deliver sturdy labels with excellent print quality and better production efficiency. The choice of materials and packaging logistics combined with smart labeling ensures direct product success.

📩 sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 https://foyottr.com

👉 Contact Us Now to request custom beverage label samples or a bulk quotation.

FAQs

What’s the best label material for cold beverages?

Polypropylene (PP) or PET are ideal for moisture resistance and cold environments.

Can beverage labels be customized with batch codes and QR links?

Yes, variable data printing allows for QR codes, barcodes, and batch traceability.

Are beverage labels food safe?

We offer FDA-compliant materials and adhesives suitable for indirect food contact.

What is the typical lead time for large orders?

Standard turnaround is 7–15 business days depending on volume and complexity.

Can I order labels in different languages?

Yes. Multilingual versions can be printed within a single order using VDP or segmented batches.