Blog

What Are Blank Labels? A Complete Guide for B2B Buyers

Blank labels serve as essential tools for operational efficiency in high-volume logistics as well as manufacturing and retail sectors. Unprinted adhesive labels provide the surface needed for printing diverse information such as barcodes, shipping addresses, SKU numbers and product descriptions on demand.

Distributors, sourcing agents and B2B procurement managers who learn about blank label production and sourcing benefit through improved cost management and customer satisfaction. The guide offers a thorough review of blank labels by examining their materials and formats as well as their applicable use cases along with printer compatibility and bulk ordering methods.

What Are Blank Labels?

Definition

Blank labels consist of adhesive-backed surfaces which have not been printed yet and support on-demand printing through direct thermal, thermal transfer, inkjet, or laser printers. Blank labels offer customization for individual dimensions and die-cut shapes while also being available in standard sizes for shipping and packaging requirements.

Key Features

- Available in roll, sheet, or fanfold formats

- Compatible with multiple printing technologies

- Made of paper or synthetic materials

- Die-cut or continuous label formats

- Multiple adhesive options available for compatibility with different surfaces and environments

Materials Used in Blank Labels

1. Facestock

- Direct Thermal Paper offers cost-effective short-term printing solutions.

- Thermal Transfer Paper: Requires ribbon, long-lasting print

- Synthetic Film (BOPP, PET): Durable, water-resistant, tear-proof

2. Adhesive Types

- Permanent adhesive options provide secure attachment solutions for corrugated boxes and poly mailers.

- Removable: For temporary labels and reusable containers

- Freezer-Grade labels are specifically engineered for food packaging and cold chain logistics applications.

3. Liner

- Silicone-coated paper backing

- The product comes with both standard thickness and thin liner options to enable extended roll capacity.

Common Applications of Blank Labels

Logistics and Shipping

- 4″ x 6″ shipping labels

- Return address labels

- International customs declarations

Inventory Management

- Barcode and SKU labeling

- Location and bin tags

- Stock rotation and shelf life tracking

Retail and POS

- Price tags

- Product identification

- Temporary promotions and markdowns

Healthcare and Pharma

- Sample and vial labels

- Internal logistics and tray tagging

- Lab test tube and ID sticker usage

Manufacturing

- Asset tracking

- Component and part labeling

- Batch number and inspection tagging

Standard Sizes for Blank Labels

| Size (inches) | Common Use Case |

|---|---|

| 4″ x 6″ | Shipping labels |

| 2″ x 1″ | Barcode labels |

| 3″ x 2″ | Inventory tracking |

| 2.25″ x 1.25″ | Return address or ID tags |

| Custom sizes | Specialty applications |

Printer Compatibility

Direct Thermal Printers

- Optimal choice for creating 4×6 high-speed shipping labels

- No ink or ribbon required

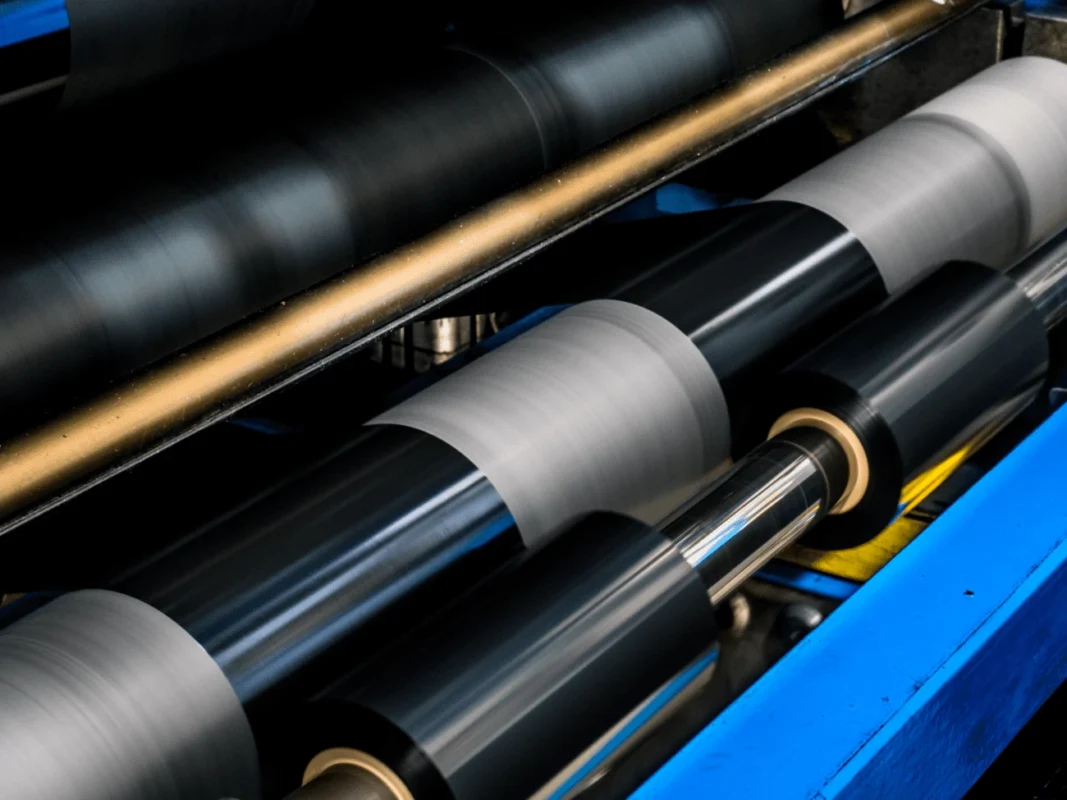

Thermal Transfer Printers

- Requires ribbon for longer-lasting prints

- Suitable for warehouse, outdoor, and industrial use

Inkjet and Laser Printers

- Typically use label sheets (8.5″ x 11″)

- Used in office settings for small batches

Mobile Printers

- Compatible with smaller blank labels

- Roll diameter typically ≤ 2.5″

- Used for field service or warehouse scanning

Blank vs Pre-Printed Labels: Which Is Better?

Blank Labels

- Offer flexibility for variable data printing

- More economical in high-mix environments

- Ideal for businesses with multiple SKUs

Pre-Printed Labels

- Best for consistent branding

- Useful for warning symbols, logos, or borders

- Require higher MOQ and longer lead time

When to Use Each

- Blank labels are the best option when a business needs both flexibility and quick operation.

- Select pre-printed labels to maintain consistent branding across products.

How to Print on Blank Labels

Printer Setup

- Set up the printer with either a label roll or sheet according to the printer specifications.

- Choose the appropriate label size through your printer driver or label software application.

- Adjust your printer settings to correct label gaps and black marks

- Test print with barcodes or text

Best Practices

- Use barcode verification tools

- Adjust both print speed and heat settings to achieve optimal performance with direct thermal printing.

- Select matte or top-coated finishes to improve the scanability of your labels.

Troubleshooting

- Faded print: Increase heat or change material

- Misalignment: Adjust guides and margin settings

- Peeling issues: Verify adhesive compatibility

Bulk Ordering Guide for Blank Labels

Minimum Order Quantities (MOQ)

- Custom jobs require a minimum of 10,000 labels.

- Customers can purchase standard sizes if they order at least 1,000 rolls.

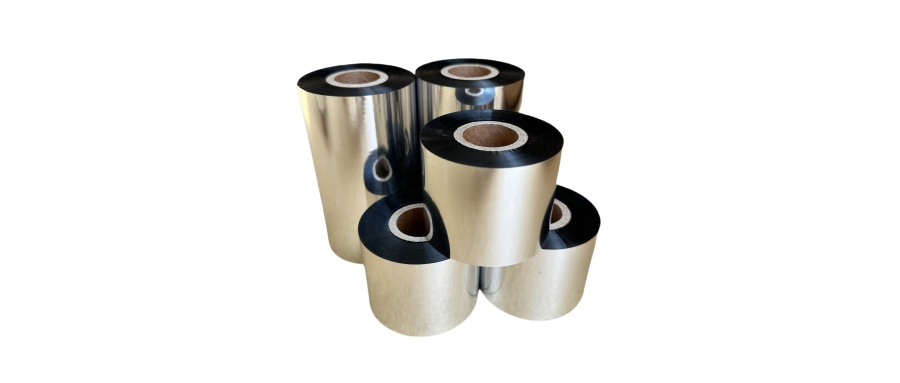

Roll Specifications

- Core sizes: 1” (desktop), 3” (industrial)

- Larger batches of labels come with an outer diameter reaching 8 inches.

- Winding: Inside or outside

Customization Options

- Die-cut shapes (rounded corners, circles, etc.)

- Adhesive type selection

- Custom pre-print (logos, borders, fields)

- Private label/OEM packaging for resellers

Packaging & Labeling

- Individually shrink-wrapped or boxed

- Custom barcode labels on roll cores

- Carton labels for warehouse efficiency

Quality Assurance

- Print quality testing (barcodes, variable text)

- Adhesive performance test

- Material and liner thickness verification

Storage and Handling Tips

- Store at 15–25°C in dry conditions

- Keep away from sunlight and humidity

- Use within 12–18 months from manufacture date

Sustainability Considerations

- Choose recyclable paper facestock

- Use liner recycling programs

- Opt for water-based adhesives when possible

- Minimize over-labeling with right-size labels

Conclusion

Blank labels provide essential functionality for any industry that needs real-time data access through barcoding and traceability systems. These labels help maintain essential operations in both warehouses and hospitals by delivering both flexibility and precision.

In operations that print thousands of shipping labels every day or handle thousands of SKUs across different product lines blank labels offer essential adaptability. When B2B buyers study the properties of materials and adhesives and their compatibility and sizing requirements they achieve improved sourcing outcomes that maximize efficiency and value.

Frequently Asked Questions (FAQ)

Can I use blank labels with any printer?

Only if the label format matches your printer’s width, core size, and print method (direct thermal, thermal transfer, etc.).

Are blank labels waterproof?

Not by default. Choose synthetic or top-coated facestock for water resistance.

What is the shelf life of blank labels?

Typically 12–18 months in proper storage conditions.

Can blank labels be customized?

Yes. You can customize the size, shape, adhesive, liner, and even add partial pre-printing.

What adhesive should I use for freezer applications?

Use freezer-grade adhesive designed for low temperatures and moisture exposure.

Looking to Source Blank Labels in Bulk?

Contact us today to request samples, pricing, or customization options.

📧 Email: sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 Website: https://foyottr.com