Blog

The Ultimate Guide to Blank Printable Labels: Everything Distributors Need to Know

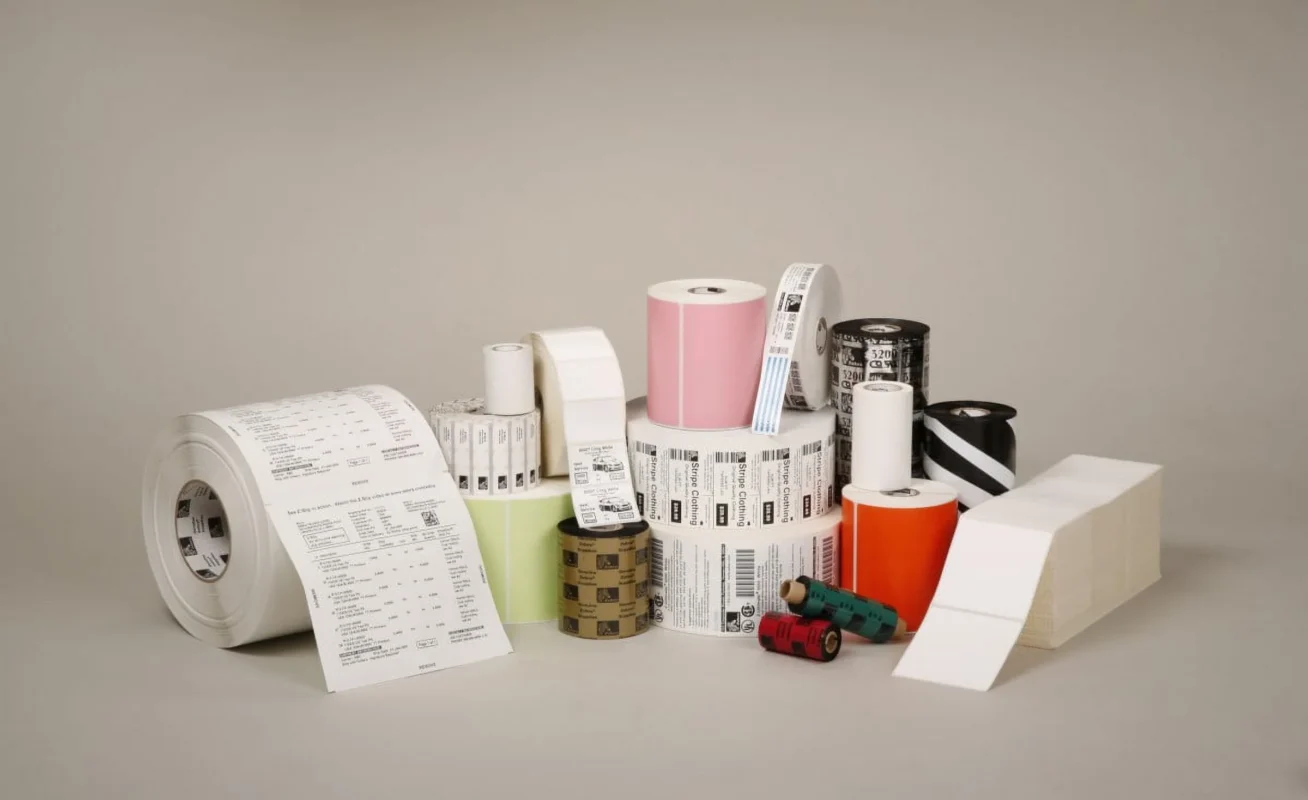

Printable blank labels appear basic yet they serve essential functions in the operations of numerous industries. Blank labels form essential components that drive operational efficiency and traceability while maintaining professionalism throughout B2B sectors by serving key roles in product packaging and inventory management as well as barcode identification and shipping logistics. Distributors, wholesalers and purchasing managers who need to deepen their knowledge about this crucial product will find the detailed guide beneficial. The Ultimate Guide to Blank Printable Labels: Everything Distributors Need to Know

We will examine various blank label options along with their materials and printer compatibility while explaining label applications and how to select appropriate label solutions for your business clients. We will explain how working with dependable manufacturers leads to better profit margins and enhanced customer satisfaction.

What Are Blank Printable Labels?

Definition and Use

Blank printable labels consist of adhesive-backed materials that do not contain any pre-existing printed information. These labels have been created for personalization through thermal transfer printing as well as inkjet, laser printing and direct thermal methods. Businesses utilize blank printable labels for printing barcodes, shipping information, branding elements, product details and additional content.

Key Benefits

- Customization flexibility

- Cost-effective for bulk operations

- Easy to integrate with automated systems

- Available in numerous sizes and formats

Types of Blank Labels

1. Sheet Labels

- Commonly used with laser and inkjet printers

- Ideal for office and light commercial applications

- Formats like A4, Letter, and Legal sizes

2. Roll Labels

- Suitable for high-speed industrial label printers

- This label works well with both direct thermal and thermal transfer printing methods.

- The product is available in core sizes including 1″, 3″, and additional options.

3. Fan-Fold Labels

- Z-fold stacked labels

- Excellent for long print runs

- Often used in shipping and warehousing

4. Die-Cut vs Continuous

- Die-cut labels: Pre-cut to specific shapes

- Continuous labels require cutting after printing because they are not pre-cut before printing.

Common Materials Used in Blank Labels

1. Paper Labels

- Budget-friendly

- Great for short-term use and general labeling

2. Synthetic Labels (PP, PE, PET)

- Water, chemical, and tear-resistant

- Synthetic labels made from PP, PE, PET materials withstand harsh environments found in industrial and outdoor settings.

3. Thermal Transfer Coated Labels

- Designed for use with ribbon

- Long-lasting print quality

4. Direct Thermal Labels

- No ribbon required

- Best for short-term labels like shipping tags

Label Adhesive Types

- Permanent: Strong bond for long-term use

- Removable: Easy to peel off without residue

- Freezer Grade: Designed for cold storage

- High-Tack: For rough or curved surfaces

Applications by Industry

Retail

- Price tagging

- Product labeling

- Promotional stickers

Logistics & Warehousing

- Barcode tracking

- Inventory ID labels

- Shipping and parcel labels

Healthcare

- Patient ID

- Lab sample tracking

- Medical packaging

Производство

- Component identification

- Quality control labeling

- Compliance marking

Blank Labels and Printers: Compatibility Tips

Inkjet vs. Laser

- Inkjet offers high-resolution color labels

- Laser printers deliver quicker results and perform better when printing black-and-white or large quantities of labels.

Thermal Transfer vs Direct Thermal

- Thermal Transfer printing requires a ribbon and is ideal for long-lasting labels.

- Direct Thermal printing eliminates the need for a ribbon but results in labels that will fade with time.

Printer Brand Considerations

Your printer specifications should match label size along with core diameter and sensor alignment requirements. Conduct testing with a small batch prior to complete implementation.

How to Choose the Right Blank Labels

1. Define End Use

What purpose does the label serve: packaging logistics safety compliance?

2. Choose the Right Material

Match durability requirements: heat, moisture, abrasion?

3. Select Adhesive Type

Permanent or removable?

4. Pick the Right Format

Sheet, roll, or fan-fold?

5. Printer Compatibility

Inkjet, laser, or thermal transfer?

Benefits of Partnering with a High-Quality Manufacturer

1. Customization Options

Deliver accurate label dimensions along with appropriate materials and adhesives that meet your clients’ industrial requirements.

2. Consistent Supply Chain

Reliable lead times and scalable production will help you prevent customer downtime.

3. Competitive Pricing for Bulk Orders

The economies of scale enable you to achieve better profit margins.

4. OEM & Private Label Capabilities

Add value with white-labeling options for distributors.

Label Templates and Software Integration

Compatible with Popular Platforms:

- BarTender

- NiceLabel

- Zebra Designer

- Microsoft Word/Excel (for office use)

A variety of manufacturers present downloadable templates in PDF or Word files to make label printing easier.

Sustainability in Blank Labels

- FSC-certified paper options

- BPA-free thermal materials

- Recyclable release liners

- Low-VOC adhesives

Conclusion

Modern commercial operations rely on blank printable labels as their essential yet unspoken backbone. Selecting appropriate label types, materials, and suppliers significantly impacts operational efficiency as well as customer satisfaction. When distributors and resellers grasp these variables they enhance their ability to serve varied markets and strengthen client bonds while boosting their profit margins.

Our team offers reliable bulk blank labels with manufacturing options that fit your needs along with responsive support.

Свяжитесь с нами | Email: sales@foyottr.com | Tel: +86-592-6018318 | Website: https://foyottr.com/

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

1. What is the least number of blank labels I need to order?

Manufacturers typically require minimum orders of 5,000 to 10,000 labels based on their size and material specifications.

2. Do you offer die-cutting for custom label shapes?

Custom die-cutting services are available to meet specific design and application requirements for our clients.

3. Can blank labels operate effectively in high-speed printing systems?

Roll labels are crafted to work efficiently with automated and high-speed printing systems.

4. Blank thermal labels have a typical shelf life of 6–12 months when stored properly in a cool, dry environment.

Blank thermal labels maintain their quality for up to 12 months when stored under cool and dry conditions. Always check the manufacturer’s specification.

5. Do you provide samples before bulk ordering?

Customers can receive sample rolls or sheets to test compatibility and verify quality before placing bulk orders.