Blog

What Are Plain Labels and How Are They Used Across Industries?

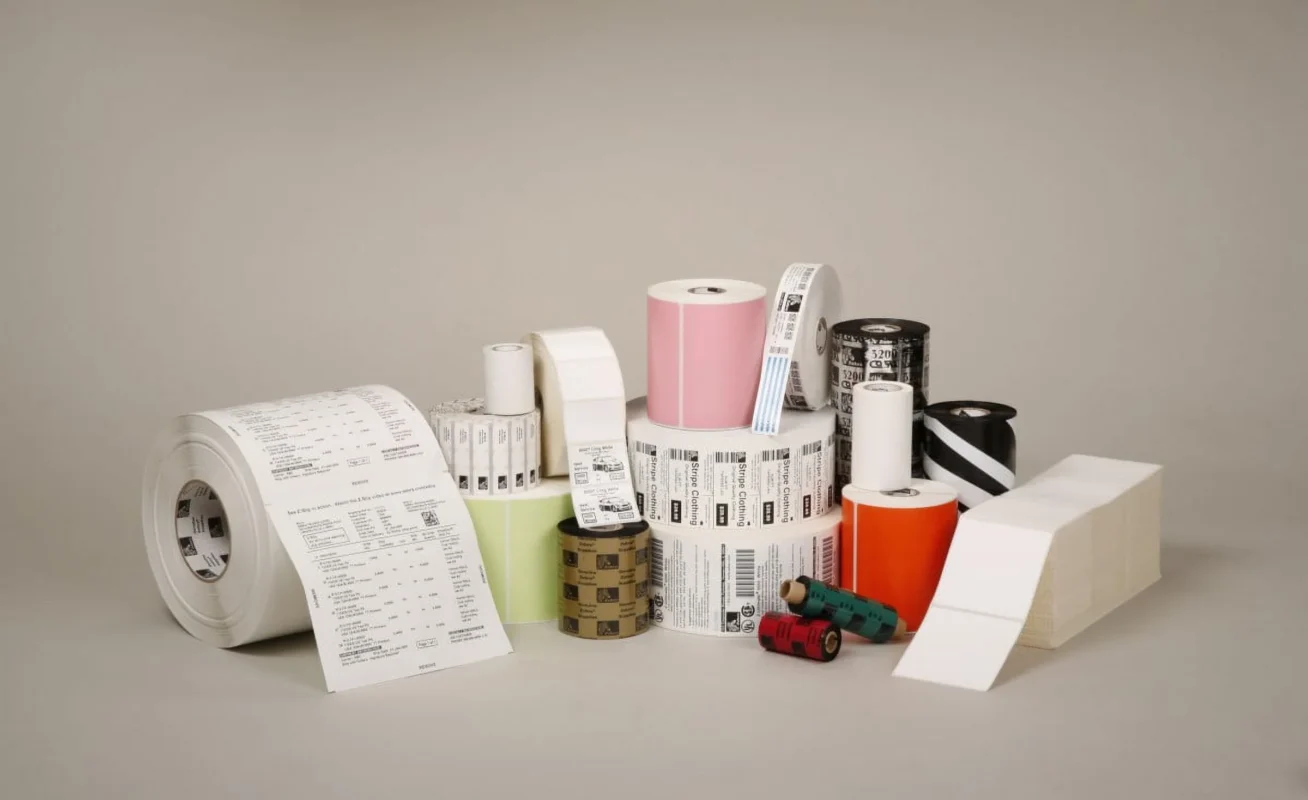

Modern business operations across retail, logistics, healthcare, manufacturing, and warehousing depend heavily on plain labels as vital organizational tools. Plain labels function as a primary product for labeling needs in industrial and commercial sectors through their applications in barcode systems, inventory tracking, product identification, and packaging compliance.

The article provides a thorough examination of plain labels and explores their fundamental types alongside printing compatibility requirements for different industry applications and comparisons to other label options. This comprehensive guide serves as your essential resource if you are a distributor, reseller, or procurement specialist who needs bulk plain label sourcing or wants to better understand their value.

**What Are Plain Labels? **

Definition

Plain labels represent unprinted adhesive stickers which users can personalize through multiple printing techniques. Manufacturers supply these labels without any print so users can add custom designs with thermal transfer, direct thermal, inkjet, or laser printing technologies.

Primary Features

- Blank surface for user-defined printing

- Compatible with multiple printing technologies

- Available in rolls, sheets, or fan-fold formats

- Customers can choose from multiple material options and adhesive types.

Why Businesses Choose Plain Labels

- Cost-effective bulk labeling solution

- Greater flexibility across product lines

- Suitable for high-volume applications

- Easy integration with existing label software

Types of Plain Labels

1. Thermal Transfer Plain Labels

- Require a ribbon to print

- Suitable for long-lasting prints

- These labels excel when used for inventory management as well as in warehouse and cold storage settings.

2. Direct Thermal Plain Labels

- No ribbon required

- Print by heat activation

- Direct Thermal Plain Labels are ideal for tasks requiring short-term labeling solutions such as shipping and food products.

3. Inkjet/Laser Plain Labels

- Sheet form (usually A4 or Letter)

- Great for office use or small businesses

- Compatible with home or commercial desktop printers

4. Roll and Sheet Formats

- Rolls: Used for industrial and automated printing

- Sheets work best when used with desktop printers or for manual labeling tasks.

5. Die-Cut vs. Continuous Labels

- Die-Cut: Pre-cut into defined sizes or shapes

- Continuous: Users define the cut after printing

Materials Used in Plain Labels

1. Paper-Based

- Economical and easy to print on

- Suitable for indoor applications

2. Synthetic Films (PET, PE, PP)

- Resistant to water, oil, and chemicals

- Ideal for industrial and outdoor use

3. Eco-Friendly Options

- FSC-certified paper

- BPA-free thermal labels

- Recyclable adhesives

Popular Adhesive Types

- Permanent Adhesive: Secure long-term bonding

- Removable Adhesive: Leaves no residue

- Freezer Grade Adhesive: Functions in sub-zero environments

- High-Tack Adhesive produces strong attachments to surfaces that display roughness or irregular texture

Top Industries That Rely on Plain Labels

Retail

- Product pricing and identification

- Inventory and SKU tracking

- Promotional tagging

Logistics and Warehousing

- Shipping labels and address tags

- Inventory control and barcode labeling

- Pallet and bin tracking

Healthcare

- Patient identification bands

- Specimen containers

- Prescription labeling

Производство

- Batch identification and traceability

- Compliance and warning labels

- Internal process tracking

Food and Beverage

- Nutritional and ingredient labeling

- Expiry and production dates

- Cold storage product tracking

Plain Labels vs. Pre-Printed Labels

When to Choose Plain Labels

- High customization required

- Labels need customization because they include variable details such as barcodes and address information along with batch numbers.

- Need for just-in-time printing and on-demand flexibility

When to Choose Pre-Printed Labels

- Brand consistency is key

- Large batch runs with identical data

- Color-coded or logo-specific designs

Cost Considerations

Businesses needing frequent label content changes find plain labels more cost-effective but pre-printed labels provide better value for designs that remain unchanged through extensive production runs.

Printer Compatibility and Tips

Choosing the Right Printer

- Thermal Printers: Best for logistics, healthcare, manufacturing

- Laser Printers deliver quick and tidy print results which make them well-suited for office settings.

- Inkjet printers produce vibrant color results suitable for retail display labels and high-quality presentation materials.

Software Integration

Compatible with:

- BarTender

- Zebra Designer

- NiceLabel

- Microsoft Word (for sheets)

Best Practices

- Match label material to printer type

- Run small test batches before full-scale printing

- Maintain label longevity by storing them in cool and dry environments

Custom Plain Label Services for Distributors

1. Size and Shape Customization

Provide clients with distinctive die-cut shapes and different label sizes.

2. Core Diameter Options

Support different printer types with label cores available in 1″, 1.5″, and 3″ diameters.

3. Branding Add-Ons

Customers can integrate brand codes or serial numbers into labels through OEM/ODM solutions.

4. MOQ Flexibility

Scale your production capabilities to meet buyer requirements with flexible production from small trial orders to large-scale manufacturing runs

Sustainability Trends in Plain Label Production

- Use of low-VOC adhesives

- The slitting and die-cutting production stages experience minimized material waste.

- Growing demand for recyclable backings and liners

Benefits of Working with a Professional Manufacturer

1. Quality Assurance

- Consistent adhesion, clean cutting, smooth surfaces

2. Production Scalability

- Fast turnaround for growing distributor needs

3. Cost-Effective Pricing

- Bulk discounts and efficient packaging

4. Global Shipping

- Being near seaports allows companies to minimize both freight time and shipping expenses.

Conclusion

Though simple in appearance plain labels serve multiple industries and business sectors across the globe. Distributors and purchasing professionals need to understand label types and materials as well as printer compatibility and use cases to make informed buying decisions. Plain labels deliver superior adaptability and value across warehouses and healthcare facilities alike, while also speeding up processes in retail settings.

Find high-quality plain labels with attractive B2B pricing options. Reach out to our expert team today.

Свяжитесь с нами | Email: sales@foyottr.com | Tel: +86-592-6018318 | Website: https://foyottr.com/

ЧАСТО ЗАДАВАЕМЫЕ ВОПРОСЫ

1. What sizes are available for plain labels?

Our inventory of plain labels includes various standard sizes as well as custom dimensions to fit specific printer requirements and application needs.

2. Clients can personalize blank plain labels according to their branding requirements.

Yes. The labels arrive blank but we provide die-cut custom shapes along with OEM packaging solutions.

3. These labels work with most common label printers including thermal and laser models.

Our label options work seamlessly with popular thermal, laser, inkjet printers and additional models.

4. Do you offer eco-friendly label options?

Absolutely. Our selection includes plain label materials that are BPA-free and FSC-certified along with recyclable options.

5. How long does it take for you to produce and ship your orders?

Lead time varies between seven and twenty days based on the order volume. Fast-track options are available for urgent orders.

📩 sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 https://foyottr.com

👉 Contact Us Now to discuss your custom label requirements!