Blog

Tag Printer: A Complete Guide for Distributors and Wholesale Buyers

In modern fast-paced business sectors such as retail and logistics the efficiency of tagging and labeling systems determines the level of productivity achieved. A dependable tag printer will optimize your operations across apparel manufacturing to retail by delivering fast and uniform product labels. Our in-depth guide explains tag printer functionality and operation while detailing available types and essential features so distributors and sourcing professionals can select the most suitable option for their supply chains.

What Is a Tag Printer?

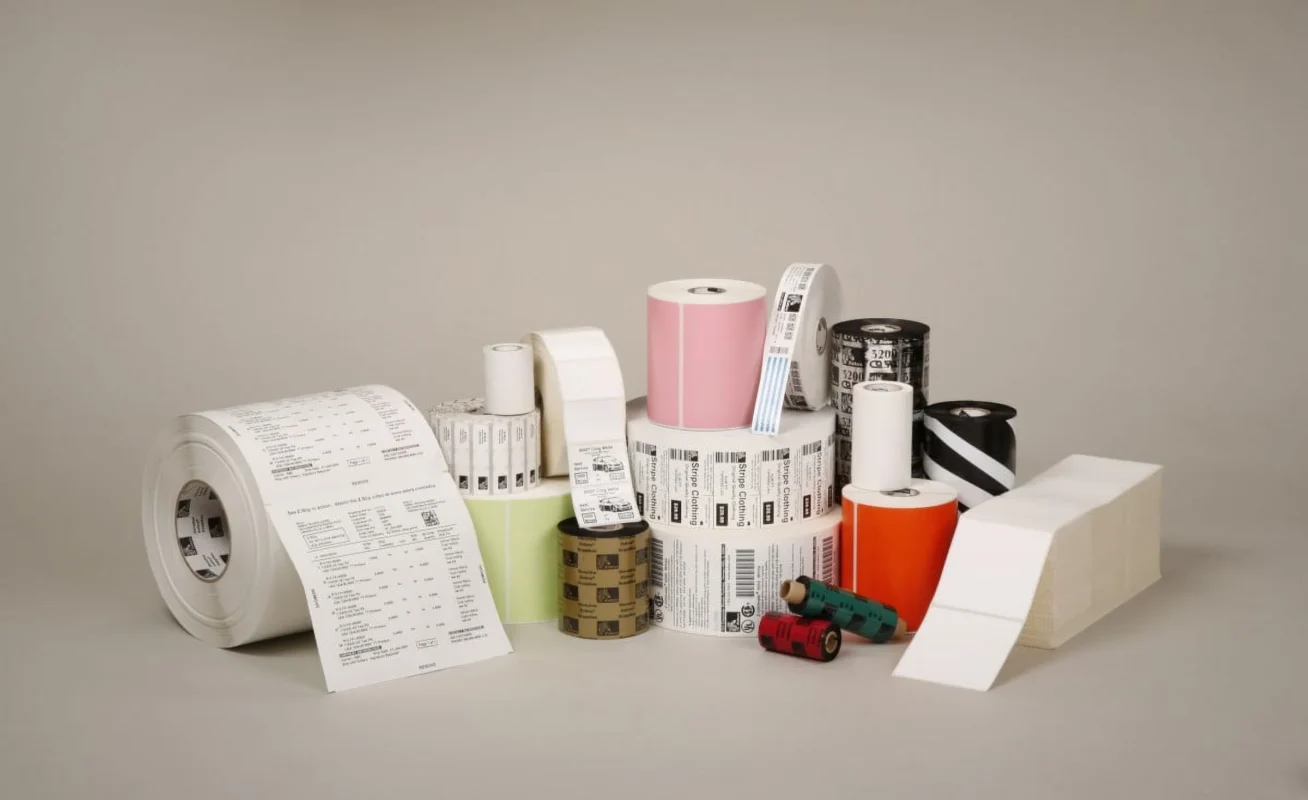

Tag printers function as specialized devices which create tags for various labeling applications including product identification and price marking. These tag printers have the capability to work with multiple materials such as paper and cardstock along with synthetic film and thermal paper.

Applications of Tag Printers

- Retail product tagging

- Apparel and fashion industry labeling

- Industrial equipment tags

- Asset tracking and inventory management

- Warehouse and logistics labeling

Types of Tag Printers

1. Direct Thermal Tag Printers

- Uses heat-sensitive paper

- Ideal for short-term labels

- No need for ribbons

- Cost-effective for temporary tags

2. Thermal Transfer Tag Printers

- Uses a ribbon to transfer ink

- Suitable for long-lasting tags

- Works with synthetic and coated tags

- Better durability and resistance to elements

3. Inkjet and Laser Tag Printers

- High-resolution printing

- Suitable for high-color, detailed tags

- Slower and more expensive to operate

When purchasing a tag printer it’s essential to evaluate specific key features.

Print Resolution

- Standard print resolution choices include 203 dpi, 300 dpi, and 600 dpi

- Higher resolution = clearer barcodes and logos

Print Speed

- Fast speeds = increased productivity

- Important for high-volume operations

Connectivity

- USB, Ethernet, Wi-Fi, Bluetooth

- Integration with POS or inventory systems

Material Compatibility

- Make sure the printer supports the specific tag stock materials you require including paper and plastic.

Software Integration

- Compatibility with label design software

- Support for barcode generation and QR codes

Size & Portability

- Consider desktop vs. industrial models

- Portable printers for fieldwork use

Benefits of Using Tag Printers for Businesses

1. Improved Efficiency

- Automates manual tagging processes

- Reduces human error

2. Brand Consistency

- Uniform label appearance across products

- Enhances professional presentation

3. Cost Reduction

- Bulk tag printing reduces per-unit cost

- In-house printing eliminates third-party expenses

4. Enhanced Traceability

- Enables barcode-based tracking

- Improves inventory visibility and accuracy

Selecting an appropriate tag printer should match your business requirements.

Identify Your Tagging Needs

- Retail vs. industrial?

- Volume and frequency of printing?

Determine Environmental Factors

- Will the tags be exposed to moisture, heat or abrasion in their intended environment?

- Outdoor or indoor usage?

Set a Budget

- When selecting a tag printer take into account the Total Cost of Ownership which includes the initial device cost along with supplies and maintenance expenses.

Consider the Supplier’s Support

- Does the supplier offer after-sales service?

- Is training or integration assistance provided?

Common Tag Printer Materials

- Matte or glossy cardstock

- Synthetic waterproof film

- Thermal-sensitive paper

- Adhesive or non-adhesive tags

Conclusion

Businesses that need effective labeling solutions find tag printers to be essential tools. Your financial results can improve significantly when you choose a tag printer that enhances operational efficiency while maintaining regulatory compliance. Distributors, wholesalers, and sourcing managers need to understand technology and choose the correct machine to fulfill end-client requirements.

FOYO provides thermal transfer ribbons and label solutions which meet specific business requirements. Our professional team stands ready to assist you with bulk tag printer and ribbon options.

FAQ

**Q1: Tag printers print on non-adhesive materials such as hang tags while label printers specialize in producing adhesive stickers or labels. **

Tag printers focus on non-adhesive materials such as hang tags whereas label printers produce adhesive stickers and labels.

**Q2: Tag printers cannot print on regular paper since they are constructed to work with thermal paper and other specialty materials. **

Tag printers function exclusively with specialized materials including thermal paper as well as synthetic film and cardstock.

**Q3: Tag printers require routine print head cleaning and proper alignment checks plus periodic replacement of ribbons and rollers. **

Maintaining long-term performance of tag printers requires consistent print head cleaning and alignment checks as well as ribbon and roller replacements.

**Q4: Do tag printers support barcode and QR code printing capabilities? **

The majority of tag printers have the capability to produce barcodes and QR codes through compatible software.

**Q5: Potential suppliers for wholesale tag printers and ribbons include FOYO which offers contact options through their website. **

You can [contact FOYO](https: Get in touch with FOYO through email or call at +86-592-6018318.

Contact Us

📩 sales@foyottr.com

📞 Tel: +86-592-6018320

🌐 https://foyottr.com/

Visit our Contact Page to get started or request a quote today.