Blog

Handheld Label Maker: A Complete Guide for Distributors and Buyers

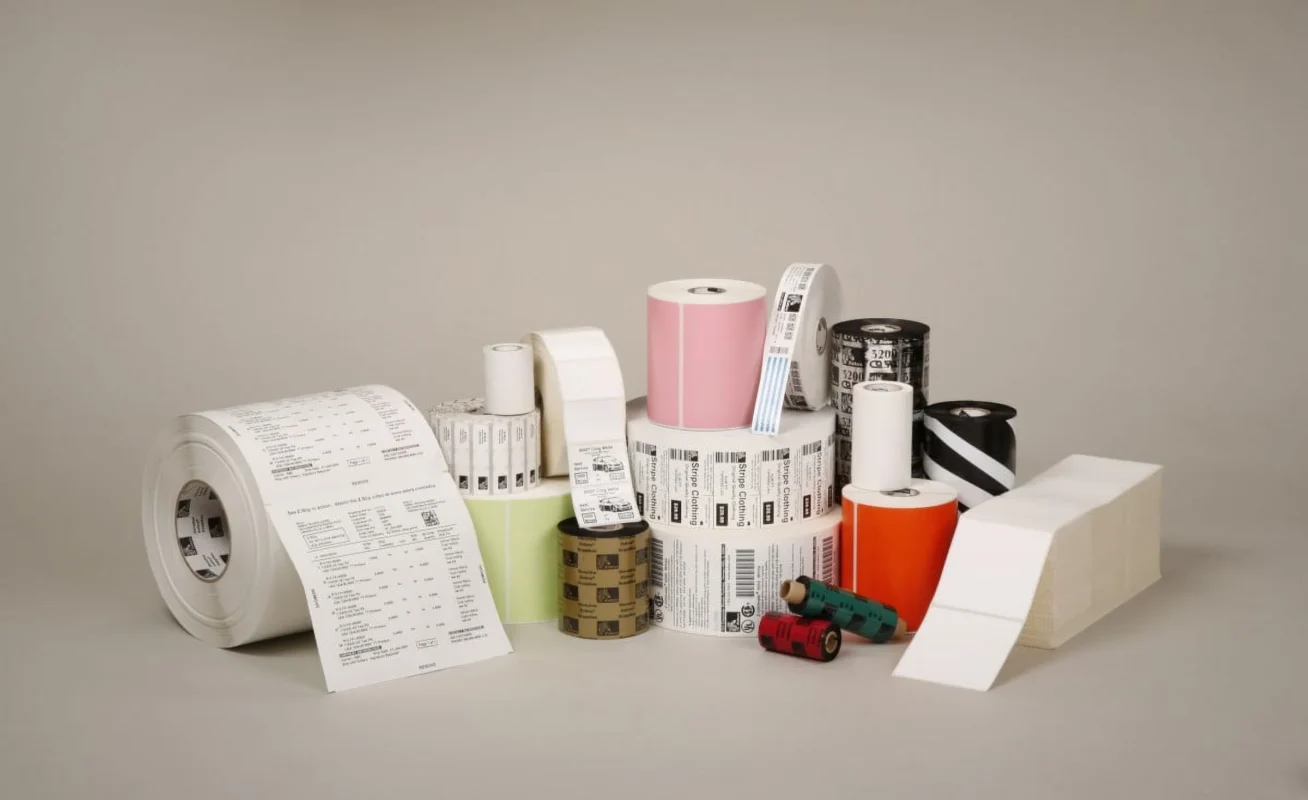

The need for portable labeling solutions has risen to unprecedented levels in today’s rapidly moving business settings. Handheld label makers provide a flexible and effective labeling system for warehouse shelves and retail inventory management to field service equipment. Understanding the features, applications, and sourcing considerations of handheld label makers enables distributors, wholesalers, and procurement professionals to add value for clients while optimizing supply chain operations.

This guide covers the functionality of handheld label makers including essential features to look for common applications and tips for selecting dependable manufacturing partners for large-scale production.

What is a Handheld Label Maker?

The handheld label maker delivers a portable printing solution which produces adhesive labels without requiring a desktop printer. Most handheld label makers operate on batteries and feature built-in keyboards or Bluetooth connections for label text input.

Key Features:

- Lightweight and battery-powered for portability

- Built-in keyboards or smartphone integration

- Thermal printing (direct or thermal transfer)

- Custom font, symbol, and layout options

- Various label tape widths and adhesive types

How Does a Handheld Label Maker Work?

Handheld label makers transfer printed characters onto label tapes by using thermal printing technology. Most label makers operate through direct thermal technology which removes the requirement for ink or toner. The printhead transfers heat directly to label paper that features a heat-sensitive coating which turns dark upon exposure.

Printing Process:

- Users can enter the text for labels through either the handheld device’s keyboard or a mobile application.

- Format the text and preview the label

- A thermal printhead activates to produce printed output directly on the tape.

- A user must manually cut and apply each printed label.

Common Applications of Handheld Label Makers

Handheld label makers enable distributors and procurement teams to support diverse industrial sectors. The most typical applications of handheld label makers include:

1. Retail

- Price tagging

- Barcode labeling

- Shelf labeling

2. Warehouse and Logistics

- Inventory management

- Pallet and bin labeling

- Location identification

3. Field Services

- Asset labeling

- Tool and equipment identification

4. Office and Administrative

- File folder labeling

- Cable management

- ID badge creation

Benefits for B2B Buyers

Portability

The design of the compact lightweight device enables its usage in remote locations along with retail floors and warehouses which lack dedicated printing stations.

Ease of Use

Most handheld label makers include user-friendly interfaces which allow non-technical workers to operate them.

Cost-Effectiveness

Handheld devices are budget-friendly for large-scale operations because they require little maintenance and cheap consumable materials.

Fast Deployment

Businesses achieve improved productivity and minimized operational delays by using handheld label makers for immediate labeling tasks.

Key Features to Look For When Sourcing

1. Battery Life and Charging

Select lithium-ion rechargeable batteries to extend operational time during fieldwork.

2. Printing Resolution

The high DPI resolution provides sharp and readable labels specifically suited for barcodes and QR codes.

3. Connectivity

Mobile apps can connect through Bluetooth or USB for syncing purposes.

4. Durability

Industrial environments require printers with shock-resistant casings and dust-proof designs to ensure reliable performance.

5. Compatibility with Label Tapes

The equipment should work with different label widths and include multiple adhesive types along with color choices.

6. OEM/ODM Customization

Opt for a manufacturer that provides custom packaging solutions as well as firmware localization and branding capabilities for your private label projects.

When selecting a supplier for large volume purchases it’s essential to evaluate their ability to deliver quality products with cost savings and timely delivery.

A reliable manufacturer selection is essential for maintaining quality standards while optimizing costs and delivery schedules. Here are key criteria to consider:

Factory Capabilities

- In-house R&D and tooling

- Quality control systems and certifications

- Capacity for large-scale production

Experience

- Years in thermal printing and labeling industry

- International clients and export experience

Customization Options

- Label maker design and feature adjustments

- Branded packaging for distributors

After-Sales Support

- Technical support and warranty coverage

- Documentation and user manuals

Why Partner with FOYO?

Established in 2009 FOYO leads the thermal labeling solutions market as a division within the FUYOU Group. Through their substantial expertise in coating processes as well as research and development together with label printing production FOYO delivers:

- OEM/ODM services

- Strict quality control

- Short lead times and flexible MOQs

- Global distribution capabilities

FOYO provides dependable performance and strong business-to-business support when you source handheld label makers for retail, logistics, or industrial applications.

Conclusion

Industries requiring mobility and efficient processing rely on handheld label makers as essential equipment. Distributors and B2B buyers who understand technical and application details achieve long-term customer satisfaction and business value. By joining forces with FOYO an established manufacturer you maintain market competitiveness through superior pricing options quality standards and customized solutions.

FAQ

Handheld label makers use which printing technology?

Direct thermal printing is used by most devices which allows them to operate without requiring ink or toner.

Is it possible to modify the handheld label maker with my brand’s design?

Yes. FOYO delivers complete OEM and ODM solutions that cover both packaging and firmware needs.

Handheld label makers are most commonly utilized in retail, warehousing, logistics, and field service industries.

The retail and warehousing sectors together with logistics providers and field service professionals represent the primary markets for handheld label makers.

Are these printers compatible with barcode formats?

The majority of available models are capable of printing both barcode and QR code formats.

Bulk orders generally require 20-25 business days to ship from FOYO depending on customization needs.

Bulk orders from FOYO usually arrive between 20 to 25 business days which varies based on customization requirements.

Contact Us

📩 sales@foyottr.com

📞 Tel: +86-592-6018320

🌐 https://foyottr.com/

Visit our Contact Page to get started or request a quote today.