Blog

What Is a Label Paper Roll and How Is It Used in Thermal Labeling?

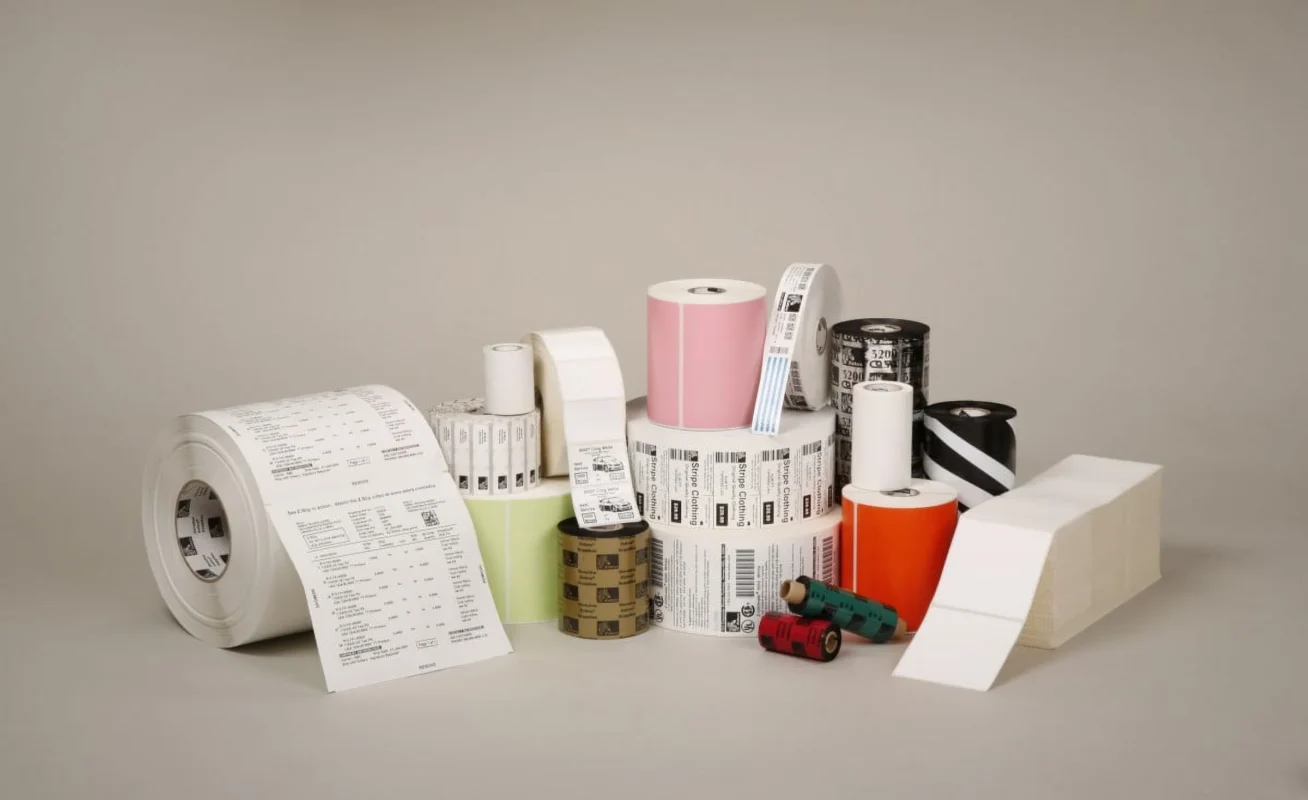

Labeling stands as a pivotal element within industrial and commercial logistical operations including retail distribution and manufacturing compliance systems. The label paper roll constitutes the primary consumable element in thermal printing systems. Label rolls provide smooth workflow and supply chain traceability for warehouse box labeling and retail item barcoding.

B2B buyers along with sourcing managers and distributors must comprehend different label paper roll types and their application compatibility to enhance operation efficiency and meet client specifications at lower costs.

The article provides information on the definition of label paper rolls and their role in thermal labeling while detailing available types, size specifications, application fields, and best practices for bulk sourcing.

What Is a Label Paper Roll?

A label paper roll consists of a continuous strip of adhesive-backed label material that is wrapped around a central core. This product functions with label printers like thermal printers to produce printed labels for packaging, shipping, inventory management and retail operations.

Label rolls come in a variety of:

- Materials (paper, polypropylene, polyester, etc.)

- Printing technologies (direct thermal or thermal transfer)

- Sizes (width, roll diameter, core size)

- Adhesives (permanent, removable, freezer-grade)

Both desktop and industrial thermal printers utilize label paper rolls which serve as a flexible solution across numerous industries.

How Does a Label Paper Roll Work?

Thermal printers utilize label rolls as the primary medium for printing. Printing technology determines the specific process utilized.

1. Direct Thermal Printing

- The printer heats the label directly.

- The paper transforms into a black image when it reacts to the applied heat.

- No ink, toner, or ribbon is needed.

- Shipping labels and food packaging labels benefit most from direct thermal printing technology.

2. Thermal Transfer Printing

- A thermal ribbon is used.

- The printhead’s heat acts upon the ribbon to transfer ink directly onto the label.

- Produces more durable and long-lasting prints.

- The thermal transfer printing method is best suited for product labels in cold chain logistics for pharmaceuticals and regulatory compliance needs.

Types of Label Paper Rolls

1. Direct Thermal Label Rolls

- Coated with a heat-sensitive layer

- Require no ribbon

- Cost-effective for short-term use

- Commonly used in logistics and retail

2. Thermal Transfer Label Rolls

- Require wax, wax-resin, or resin ribbons

- Provide high print durability

- Suitable for synthetic materials and outdoor use

3. Pre-Printed Label Rolls

- Custom-printed with branding, QR codes, or symbols

- Excellent for rapid production tasks when printer capability is restricted

4. Die-Cut vs. Continuous Rolls

- Die-cut: Labels are pre-sized and perforated

- Custom sizing from roll to roll is possible with this type.

Label Paper Roll Construction

Label rolls typically have:

- Facestock (paper or film base)

- Adhesive layer (permanent, removable, freezer-grade)

- Liner (silicone-coated paper backing)

A cardboard or plastic core supports the layers which are then placed into a thermal printer for operations.

Common Label Roll Specifications

| Feature | Options |

|---|---|

| Width | 25mm to 220mm+ |

| Outer Diameter | 100mm to 300mm |

| Core Size | 1” / 1.5” / 3” |

| Adhesive Type | Permanent, removable, freezer-grade |

| Label Format | Die-cut or continuous |

| Material | Paper, PP, PE, PET |

| Roll Winding | Inside wound / outside wound |

Matching Label Rolls with Printers

1. Determine Printer Type

- Desktop or industrial?

- Flat-head or near-edge printhead?

2. Check Roll Specs

- Ensure compatibility between label roll width, core diameter, and maximum roll diameter with your printer’s loading system.

3. Select Compatible Materials

- Select label materials that are compatible with the printer type because for example thermal transfer printers require matching label materials with the appropriate ribbon.

4. Identify Winding Direction

- Industrial systems often need rolls that are wound from the inside or outside.

Label Paper Rolls serve essential functions within business-to-business industries.

1. Logistics & Warehousing

- Shipping labels

- Barcode tracking

- Inventory management

2. Retail & E-Commerce

- Shelf labels

- Pricing tags

- Product SKU labels

3. Food & Beverage

- Fresh produce tags

- Nutrition information

- Cold chain compliance labels

4. Healthcare & Pharmaceuticals

- Prescription labeling

- Sample tracking

- Lab vial labels

5. Manufacturing

- Asset labels

- Serial number and product identification

- Instructional packaging labels

Benefits of Using Label Paper Rolls

- High throughput: Compatible with automated labeling machines

- The label paper rolls deliver clear imaging which ensures barcode and QR code readability.

- The product meets printing requirements for both small-scale and large-scale operations.

- Rolls provide economical bulk printing thanks to reduced changeover needs.

- Compatible with various adhesives and materials while supporting different coatings

Essential guidelines for procuring label paper rolls in large quantities

1. Define Application Environment

- Indoor vs outdoor, cold storage, moisture exposure?

2. Request Samples for Testing

- Test print quality together with both adhesion strength and environmental resistance levels

3. Confirm Printer Compatibility

- Prevent jamming and misalignment by ensuring all specifications match correctly

4. Plan for Forecasted Volume

- Larger orders reduce per-unit cost

- Prevent stockouts by measuring demand on a monthly or quarterly basis.

5. Ask About Custom Options

- Custom options include logo printing capabilities along with special die-cut dimensions and branded packaging liners.

6. Verify Certifications

- RoHS / REACH compliance

- Food-contact safety (for indirect food use)

- ISO quality systems

Conclusion

The core component of any thermal labeling system consists of label paper rolls. Label paper rolls enable efficient labeling solutions across warehouses and laboratories through fast, compliant, and clear processes. The selection of appropriate label types requires consideration of printing methods and material compatibility with equipment to achieve consistent performance.

Selecting direct thermal rolls for quick logistics operations or thermal transfer rolls for extended tracking purposes will enable businesses to cut costs and minimize printer downtime while boosting customer satisfaction by understanding roll specifications and bulk sourcing options.

📩 sales@foyottr.com

📞 Tel: +86-592-6018318

🌐 https://foyottr.com

👉 Contact Us Now to get personalized advice or a quote for your label paper roll requirements.

FAQs

Are label paper rolls compatible with all thermal printers?

No. Always check printer specifications like core size, roll width, winding direction, and print technology (direct or transfer).

Can I order custom-sized label rolls?

Yes. You can customize dimensions, die cuts, core size, adhesives, and even pre-print elements.

What’s the shelf life of label rolls?

Typically 12–24 months when stored in a cool, dry environment.

Do you offer freezer-safe label paper rolls?

Yes. Freezer-grade adhesives and materials are available for cold chain applications.

What is the minimum order quantity (MOQ) for bulk purchases?

MOQ depends on size and material but usually starts from 1,000 to 5,000 rolls per configuration.